5 Gallon Filling Machine

Fully automatic 5 gallon water filling machine line. Our integrated 5 gallon washer filler capper machine handles 150-1200 BPH with ≤±1% accuracy. Turnkey 5 gallon water production line solutions available.

You are here: Home » 5 Gallon Filling Machine

Transform the way you package large quantities of water

Welcome to the future of large scale water bottling. The MG Machine 3-5 gallon filling machine series is the perfect solution for automated and sanitary production of purified, mineral and distilled water. This tunnels system was designed from the ground up for the demanding requirements of 5 gallon barrel filling, and offers a complete tunnel solution that includes rinse, fill, cap and cap sort/dump in one.

Made of high quality SUS304 stainless steel and intelligent Siemens PLC controlled, it can avoid manual operation, no second pollution, save cost for working greatly—represent your pursuit of quality and strength in manufacturing industry.

The Integrated 3-in-1 Production Line

Our flagship product is the automatic 5 gallon filling machine, a sophisticated 5 gallon washer filler capper machine where three critical stages unite in one continuous, automated flow.

All-in-One, Hygienic Tunnel Design

Integrated Process: The bottle washer, filler and sealer are combined together to one piece of filling equipment the filling line. The whole operation takes place in a cleanroom, so no secondary contamination can be introduced in the sensitive filling step.

Advanced Washing: Uses liquid washing and elution for several sterilization treatments. The cleaning solution is suitable for recirculation, the cleaning is both effective and the water usage minimal.

High-Speed, Precision Automation

Intelligent Control: The system is based on an intelligent control system, allowing a high level of automation for smooth operation, accurate sequencing and easy operator management via touch screen HMI.

Gentle, Secure Sealing: The capper applies a synchronous chain plate gland principle which can seal various plastic anti-counterfeit covers tightly and gently without scratch.

Cap Sterilization: It is equipped with a water spraying system to sterilize the bottle caps automatically ensuring they are clean before capping.

Robust & Reliable Construction

Superior Quality Materials: The chassis is made of high-quality SUS304 stainless steel, which is corrosion-resistant and easy to clean and maintain.

First-Class Components: The major electric system is of Siemens, OMRON etc ., the pneumatic circuit of AIRTAC imported components, assuring long-term stability and performance.

Mechatronic Design: This is a real automatic barreled machine combining motor, electric, and pneumatic systems in a single block.

The Automation Advantage: Machine vs. Manual Stacking

Upgrading your 5 gallon water production line isn’t just about the filler. The downstream handling is where automation delivers massive ROI, as shown in this critical comparison:

| Factor | Traditional Manual Stacking | MG Machine Automatic Stacking Method |

|---|---|---|

| Labor Required | At least 3-4 operators per shift for 1200 BPH. Heavy, repetitive workload. | Only 1 operator needed. Easy operation, often manageable by one person. |

| Labor Intensity | Physically demanding work leading to fatigue and high turnover. | Effortless operation with mechanical lifting; no heavy lifting required. |

| Hygiene & Sanitation | Manual contact with buckets; lower sanitary grade, higher contamination risk. | Fully automated process; no manual contact with bottles, ensuring superior hygiene. |

| Container Loss/Damage | High damage rates from drops, mis-stacks, and re-handling when stacks are too high. | Gentle and stable lifting/discharging. Minimal barrel loss and damage. |

| Business Perception | Appears outdated; cannot meet the efficiency demands of growing clients. | Shows enterprise strength, enhances market competitiveness, and appeals to major buyers. |

Complete Technical Specifications

Our range of 5 gallon bottle filling machines is designed to scale with your business, from small plants to large-scale producers.

| Model | Capacity (5 Gallon BPH) | Total Power | Dimensions (L x W) | Height | Weight |

|---|---|---|---|---|---|

| QGF-150 | 150 BPH | 1.5 KW | 2.3 x 1.9 m | 1.8 m | 800 kg |

| QGF-300 | 300 BPH | 3.8 KW | 2.5 x 1.9 m | 2.0 m | 1,500 kg |

| QGF-450 | 450 BPH | 4.5 KW | 2.8 x 2.15 m | 2.2 m | 2,000 kg |

| QGF-600 | 600 BPH | 5.2 KW | 3.1 x 2.5 m | 2.3 m | 2,500 kg |

| QGF-900 | 900 BPH | 6.2 KW | 3.8 x 2.8 m | 2.5 m | 2,800 kg |

| QGF-1200 | 1200 BPH | 7.8 KW | 4.5 x 3.3 m | 2.6 m | 3,500 kg |

General Specifications for All Models:

Suitable Containers: 3-5 Gallon (approx. 18.9L) PC/PET bottles. Round or Square shapes.

Filling Method: Gravity Filling at Ambient Temperature.

Filling Accuracy: ≤ ±1%

Power Supply: 380V, 3 Phase, 50Hz

Production Capacity: Adjustable, from 100 to 1500 BPH across the model range.

Main Material: SUS304 Stainless Steel.

Control System: Siemens PLC + Touch Screen HMI.

Customizable & Scalable Production Solutions

We understand that no two plants are identical. Our 3 5 gallon filling machine systems are designed for flexibility.

Bottle Adaptation

Easily handle different 5 gallon bucket or barrel shapes (round/square) with purchasable change-over parts. A dedicated bottle separating system is available for square containers.

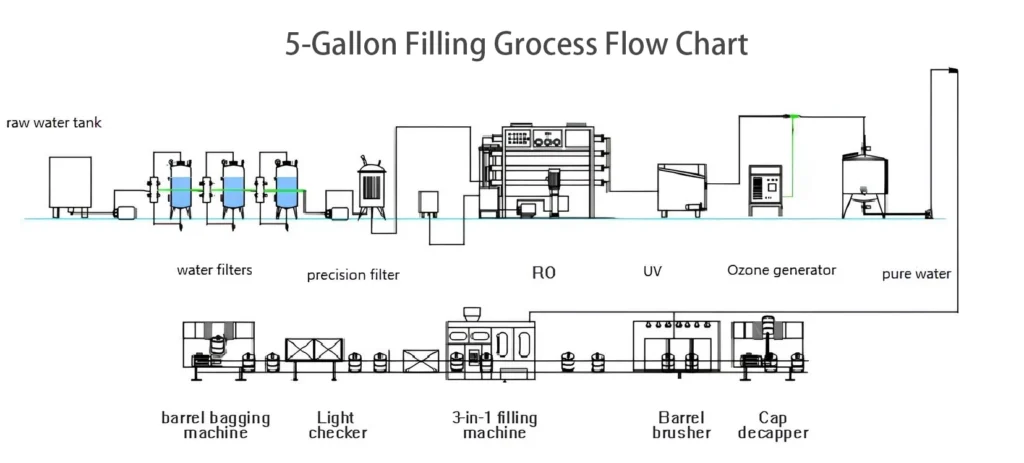

Line Integration

This machine forms the heart of a complete 5 gallon water production line. We provide CAD layout designs and can integrate upstream (e.g., blow molders) and downstream (e.g., automatic stackers, shrink wrappers) equipment for a turnkey solution.

Specialized Layouts

Our engineering team can design special layouts tailored to the unique constraints of your factory floor.

Premium Machine Configuration

The reliability of our automatic 5 gallon filling machine is built on a foundation of high-end components:

| Item | Name / System | Specification / Brand |

|---|---|---|

| 1 | Conveyor Structure | Servo Stepping Motor |

| 2 | Electrical Control System | MITSUBISHI Programmable Controller, Centralized Touch-Screen Control |

| 3 | Pneumatic Control System | AIRTAC, PLC Controlled |

| 4 | Head Gripper Lifting System | 4×1 Collet Chuck |

| 5 | Main Lifting System | Pneumatic Clamping and Lifting |

| 6 | Main Machine Material | SUS304 Stainless Steel |

we’re here to all your questions

What types of water can it fill?

Designed for still, non-carbonated liquids—purified, mineral, and distilled water in 3–5 gallon containers.

How is hygiene ensured?

Multi-layered: enclosed process tunnel, recirculating bottle wash, cap sterilization, and food-grade stainless steel with CIP.

Can it handle both 3‑gallon and 5‑gallon bottles?

Yes, adjustable for 3–5 gallons (11–19 L) via control system and change parts.

Difference between filling machine and production line?

Yes. Models BDCGF14-12-5 Filling machine = core 3-in-1 washer-filler-capper. Production line = filling machine + all peripheral equipment (pre-rinsers, labelers, stackers, etc.).

After-sales support and warranty?

2-year warranty, installation guidance or on-site support, operator training, remote troubleshooting, and genuine spare parts supply.