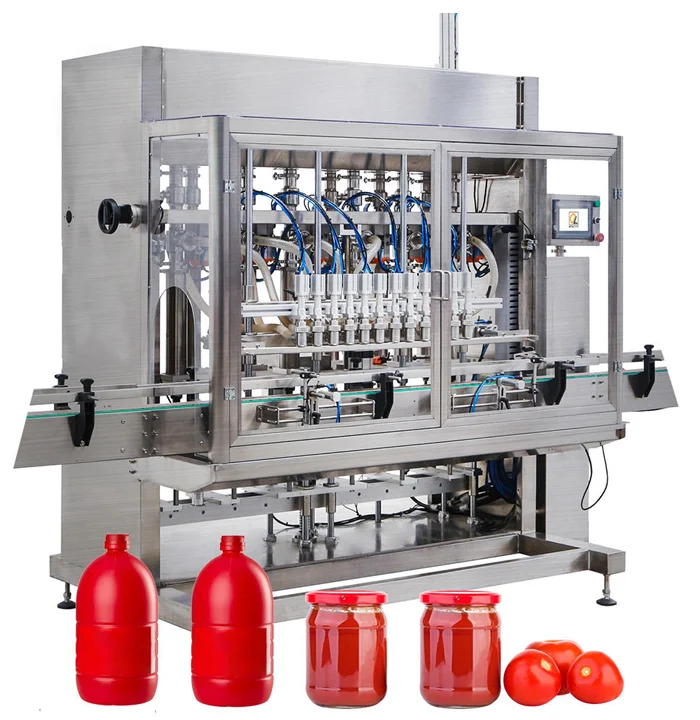

Condiments Filling Machine

The piston filling machines of MG Machines perfectly dispense with accuracy thick sauces, honey and cosmetics. Our tomato sauce filling machine & honey filling machine will get clean and accurate fills. Solutions for your product filling machines for Customized daily chemical products.

You are here: Home » Condiments Filling Machine

Precision Filling for Thick & Sensitive Products

Filling dense pastes, cream based sauces or thick liquids come with its own set of challenges, such as drips, uneven dosing and waste of product. MG Machine is the leading manufacturer of the plug and piston filler for low to high viscosity products with unparalleled accuracy and dependability.

Whether it’s tomato sauce, honey, spices or exceptional daily chemical items, when you bottle with our technology you achieve clean filling, accurate volumes and productive work. In addition to individual machines, we provide total, tailor made filling and packaging systems for the special characteristics of each product.

Core Technology: The Piston (Plug) Filling Advantage

Unlike gravity or pressure fillers, our seasoning filling machine uses a robust, mechanically-driven piston system, making it the undisputed champion for non-flowable products.

How the Precision Piston System Works:

Intake Stroke: Filling valve which is pneumatically operated goes down into the product hopper. A solenoid valve causes the piston to retract, pulling a known amount of material into the dosing chamber.

- Discharge Stroke: The valve shifts to filling position over the jar. The valve is opened from the container mouth by means of a cam, and the piston advances, cleanly filling the bottle without dripping.

- Adjustable Precision: The fill volume may be easily modified by adjusting the stroke length of the piston (via a mechanical block or digital setting), giving unparalleled stability and reliability in the consistency of the batches.

Features of linear filling machines

Built for Viscosity

Excellently handles thick slurry materials, pastes, creams, and chunks where other fillers fail.

Premium Global Components

Utilizes Germany Festo pneumatic parts, Japanese mechanical components, and Mitsubishi electric controls for unmatched durability and stable operation.

Clean & Contamination-Free

Plug-style valve design minimizes air inclusion and prevents stringing or tailing, crucial for aesthetics and hygiene.

User-Centric Design

Features real-time volume adjustment, a total bottle counter, variable speed conveyor, and a sturdy stainless-steel frame. Easy to clean and maintain without special tools.

3-in-1 filling features

Integrated 3-in-1 System

Combines washing, filling, and capping in a single machine for efficiency.

Precise Dosing

Plug/piston filling ensures consistent volume without dripping or waste.

Viscosity-Optimized Handling

Designed specifically for thick sauces like tomato ketchup, honey, or condiments.

Hygienic & Easy to Clean

All contact parts are food-grade and CIP-capable.

Versatile & Reliable

Suitable for small to large batch production with minimal downtime.

Technical Specifications: CGF Series Three-in-One Machines

Our integrated washer-filler-capper models are ideal for ready-to-fill containers requiring rinsing.

| Model | CGF18-18-6F | CGF24-24-8F | CGF32-32-10F |

|---|---|---|---|

| Machine Name | Washing Filling Capping Three-in-One | Washing Filling Capping Three-in-One | Washing Filling Capping Three-in-One |

| Heads (Wash/Fill/Cap) | 18 / 18 / 6 | 24 / 24 / 8 | 32 / 32 / 10 |

| Productivity | 4,000 – 6,000 BPH | 6,000 – 8,000 BPH | 8,000 – 12,000 BPH |

| Motor Power | 4.4 kW | 5.2 kW | 6.2 kW |

| Overall Dimensions (mm) | 2800 x 2150 x 2300 | 3100 x 2300 x 2400 | 3880 x 2880 x 2500 |

| Weight | 4.5 T | 6.5 T | 7.5 T |

| Applicable Bottle | Glass/PET: Ø50-92mm, H:150-340ml, Vol: 350-2000ml | ||

| Applicable Cap | ROPP (screw cap) or Crown Cap | ||

| Filling Temperature | Ambient or 0-4°C (Cool Fill) |

Design Parameters for Sensitive Products (e.g., Sauces):

Filling Temperature: Up to ~82°C for hot-fill products.

Sterilization Support: Options for ozone cap rinsing (≥10s) and sterile air drying to meet high hygiene standards.

Container Flexibility: Handles round PET/glass. Square bottles require an added separating system.

Product Application Spectrum: From Kitchen to Cosmetic

Our piston filling machines are engineered for versatility across industries with demanding viscosity requirements.

| Product Category | Examples | Key Filling Challenges | How Our Machine Solves It |

|---|---|---|---|

| Food & Condiments | Tomato paste, ketchup (tomato sauce filling machine), mayonnaise, mustard, fruit jams, syrups. | Aeration, dripping, inconsistent portioning, containing particulates. | Positive piston displacement ensures accurate, repeatable fills without whipping in air. Clean-cut valve stops drips. |

| Honey & Spreads | Liquid honey, creamed honey, nut butter, chocolate spread (honey filling machine). | Slow flow, stringing, difficult to clean. | Robust piston handles high viscosity. Programmable speeds allow gentle handling. Full CIP capability. |

| Seasonings & Sauces | Soy sauce, oyster sauce, salad dressing, hot sauce (seasoning filling machine). | Variable viscosity, presence of herbs/spices, acidic corrosion. | Corrosion-resistant materials (SUS316 optional). Large valve diameters for particulates. |

| Daily Chemical & Cosmetics | Lotions, creams, shampoos, gels (daily chemical product filling machine). | High value, stringent hygiene, diverse container shapes. | Ultra-clean design with optional sanitary finishes. Gentle on delicate emulsions. Easy changeover for different bottles. |

| Pharmaceutical & Oils | Ointments, petroleum jelly, cooking oils, motor oils. | Precision dosing, product recovery, no cross-contamination. | High filling accuracy (≤ ±0.5%). Minimal dead volume in cylinders. Easy product flush between batches. |

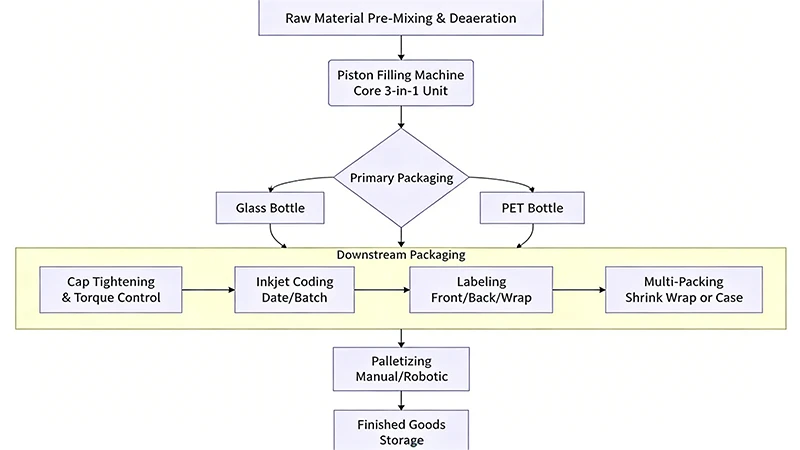

Complete Line Integration: From Bottle to Pallet

We provide complete turnkey projects. A standard line for sauces or honey in PET/glass bottles may include:

Choose MG Machine for Reliable Viscous Product Filling

Application Expertise

We understand the rheology of your product. Our engineering team doesn’t just sell a machine; we provide a processing solution to handle particulates, prevent separation, and maintain texture.

Minimal Product Waste

The closed, positive displacement system ensures nearly 100% product recovery with no drip loss, maximizing your yield on expensive ingredients.

Future-Proof Flexibility

Modular design allows for easy integration of additional features: nitrogen flushing (for oxidation prevention), weight checkers, or vision inspection systems.

Global Compliance & Support

Machines are built to meet international standards (CE, FDA-contact materials). We provide comprehensive support from factory layout to on-site training and spare parts.

we’re here to all your questions

Can it handle products with solids like chunky salsa or preserves?

Yes. Larger piston cylinders and wide-path valves let particulates pass without clogging for consistent filling.

How about different container shapes and sizes?

Adjustable frame and specific change-over parts (guide rails, plates, nozzles) allow quick switch between bottle sizes and shapes; square bottles use a separating system.

Is it suitable for corrosive products?

Yes. Standard SUS304 stainless steel can be upgraded to SUS316 or coated parts for acidic or corrosive products.

How is cleaning handled?

Hopper, piston, and valves are tool-free removable for manual cleaning; optional CIP systems automate cleaning and sanitization.

What is the filling accuracy?

Piston fillers achieve ±0.5–1.0% accuracy, depending on viscosity and particulates, ensuring precise, cost-effective filling.