Auxiliary Equipment

MG Machine’s piston filling machines handle thick sauces, honey, & cosmetics with precision. Our tomato sauce filling machine & honey filling machine ensure clean, accurate fills. Customizable daily chemical product filling machine solutions.

You are here: Home » Auxiliary equipment

Filling machine auxiliary equipment

A filling machine is not enough to ensure the smooth running of a drink production line. We offer a full range of ancillary equipment to cover all needs of the process, such as water treatment, bottle formation, sterilization, labeling, packaging and logistics.

With the best-in-class sub-systems, we provide automation solutions to make your production fully automated with high quality and operational stability for your liquid products such as water, carbonated beverages, juice, tea, milk, beer and more.

Water Treatment System

An essential command module to clean incoming water to high standards of hygiene, safety and taste. The system employs multianion and multication exchange, activated carbon adsorption, softening, reverse osmosis, and UV/ozone sterilization.

It eliminates sediments, organic impurities, odors and living bacteria and provides a stable purified water which guarantee the product uniformity and the safety of the downstream apparatus.

Beverage Blending System

It accurately blends water, syrup, concentrates and additives for consistent taste, brix and carbonation level.

Recipe management (including recipe creation/modification/deletion), CIP (cleaning in place) capability, and real-time monitoring are all available via automation, and the system ensures precise formulation for a range of beverage types.

Preform & Cap Injection Machine

Outputs high quality PET preforms and caps with uniform wall thickness and good material integrity. Stable repeatable performance, these machines allow complete control in-house to produce preforms and caps, reducing material and outsourcing cost.

They are the exact match for your downstream blowing and capping machines that deliver better efficiency, reliability and higher quality packaging throughout your line.

Bottle Blowing Machine (Blow Molding)

We make bbq carrier bags, preforms and PET bottles in 250ml to 2000ml sizes, round, square or your shape specifications.

The range includes two models of automatic (high-speed, high-output) and semi-automatic (most affordable for small/medium capacity) configurations. Customizable output from 1,000 to 50,000+ bottles per hour.

Sterilization & Pasteurization Equipment

Pasteurizing Machine – That is why the warm heat treatment of sensitive drinks.

Tubular Sterilizer – Tube-in-tube design for handling pulp, particles, and viscous liquids. Juice & Dairy High-Performance Ideal for juice & dairy. Price Range: ~USD 30000-40000.

Plate sterilizer - plate heat exchanger for clear beverages (water, tea, milk). Energy efficient and cost effective. Price Range: ~USD 8000-10000.

Pasteurizing Tunnel- For bottled/canned juice: uses controlled heating and spray cooling to achieve safety and shelf life. For carbonated beverages: with bottle warming to avoid condensation. For beer: multi-zone pasteurization protect carbonation and foam stability.

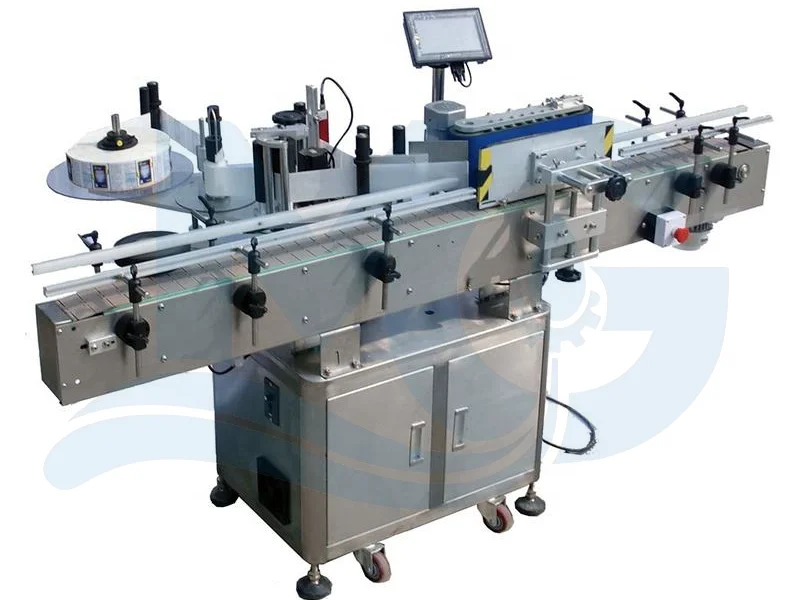

Labeling Machine

OPP Labeling Machine – Uses BOPP/OPP wrap‑around labels with hot‑melt glue. Low label cost, high speed, strong adhesion, ideal for large‑capacity water/beverage lines.

Self‑Adhesive Labeling Machine – Applies pre‑cut sticker labels without glue. High accuracy, clean finish, easy changeover, suitable for premium products and multi‑size production.

Packaging Machine

Group Packing Machine – Arranges bottles/cans into groups and wraps with shrink film. High speed, low material cost, secure packaging for transport.

Carton Packing Machine – Automatically loads bottles/cans into cartons for superior protection and stacking strength. Ideal for premium brands and long‑distance shipping.

Conveyor System

Connects all line equipment—from blowing and filling to labeling and packing—ensuring smooth, continuous bottle transfer, reducing manual handling, and improving overall line efficiency.

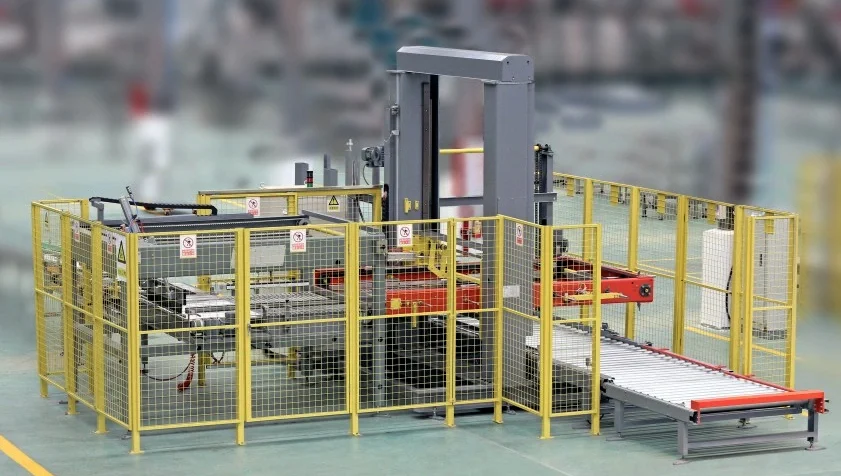

Palletizer & Depalletizer

Connects all line equipment—from blowing and filling to labeling and packing—ensuring smooth, continuous bottle transfer, reducing manual handling, and improving overall line efficiency.

Automated Warehousing System

Combine smart racks, AGVs/robots, and WMS software to control raw materials and finished products. Improves storage density, speeds up loading/unloading, reduces labor, and supports rapid, accurate order fulfillment.

Raw Materials & Consumables Supply

We also provide or source high‑quality preforms, caps, labels, and cartons tailored to your container specifications, ensuring supply chain continuity and packaging consistency.

Application Areas

Water – Purified, mineral, sparkling

Carbonated Soft Drinks – SODA, cola, flavored carbonates

Juices & Nectars – With/without pulp, cold‑fill or hot‑fill

Tea & Coffee‑Based Drinks – RTD tea, milk tea, canned coffee

Dairy & Plant‑Based Beverages – Milk, yogurt drinks, almond/oat milk

Beer & Cider – Pasteurization tunnels, carbonation control

Sports & Energy Drinks – Precise blending, sterile processing

Technical Highlights

Blowing Machine: Output up to 50,000 bph; servo‑driven for energy savings; quick mold change.

Plate Sterilizer: Heat recovery ≥90%; CIP/SIP compatible; PLC control with HMI.

OPP Labeler: Speed up to 45,000 bph; glue consumption <1.5g/bottle.

Carton Packer: Capacity up to 25 cases/min; adjustable for various bottle/can sizes.

Palletizer: Layer capacity up to 2,500 kg; robotic models with 6‑axis flexibility.

we’re here to all your questions

What factors should I consider when choosing between a tubular and a plate sterilizer?

Consider product viscosity and pulp content. Tubular sterilizers handle viscous and particulate liquids better, while plate units are more efficient for clear, low‑viscosity beverages.

Can I use the same labeling machine for different bottle shapes?

Yes, both OPP and self‑adhesive labelers allow quick adjustment for different bottle diameters/heights. Self‑adhesive models offer easier changeover for short runs.

Is it cost‑effective to invest in a preform injection machine?

For high‑volume producers, in‑house preform and cap manufacturing reduces unit costs, ensures supply stability, and allows customization of neck finishes and cap designs.

How does an automated warehouse system benefit a beverage factory?

It increases storage density, reduces manual handling errors, speeds up order dispatch, and provides real‑time inventory tracking—key for large‑scale operations.

What after‑sales support do you offer?

We provide installation supervision, operator training, remote troubleshooting, spare parts supply, and preventive maintenance contracts to ensure long‑term equipment performance.