Beverage Blending & Mixing Systems

Precision beverage blending and mixing systems engineered for consistent taste and reliable batch-to-batch quality across juice, dairy, tea, and functional drink production lines.

You are here: Home » Beverage Blending System

Where Perfect Water Meets Perfect Flavor

The path from clean water to a truly great drink depends on one vital step: precision blending. A poorly balanced combination of syrup, concentrates, sweeteners and water impacts flavor, brand integrity and profitability.

Our fully automated Beverage Blending Systems are designed to take the guesswork out of the process. Working with your water treatment plant, they provide precision dosing, mixing and carbonating, so that each bottle, can or keg is exactly to your sensory and Brix profile. We have the technology to enable your recipe to be perfectly reproduced in a scaleable, dependable production real-world.

Why Automated Blending Delivers Better Consistency

Achieving the perfect blend is a scientific process. Manual or semi-automatic methods introduce variability, while our turnkey systems guarantee control.

| Aspect | The Problem with Manual/Simple Mixing | Our Automated Blending System Solution |

|---|---|---|

| Recipe Accuracy | Human error in measuring leads to batch-to-batch taste drift and off-spec product. | PLC-controlled precision dosing of all ingredients (syrup, water, acid) to within ±0.5% of set recipe. |

| Carbonation (CO2) Control | Inconsistent CO2 levels cause flat or over-foamy products. “Fizz” is a key quality indicator. | In-line carbonation with continuous monitoring of temperature, pressure, and CO2 flow for stable, precise Volumes of CO2. |

| Production Efficiency | Slow batching, long mixing times, and frequent clean-downs limit throughput and increase labor costs. | Continuous in-line blending for non-stop production. Rapid CIP (Clean-in-Place) cycles minimize downtime. |

| Water-Deaeration | Dissolved oxygen in water accelerates oxidation, damaging flavor and shortening shelf life. | Integrated deaeration module removes dissolved oxygen prior to blending, preserving fresh taste and aroma. |

| Scale & Flexibility | Difficult to scale up; recipe changes are slow and prone to error. | Highly scalable design. Store and execute hundreds of recipes instantly via the HMI touchscreen. |

| Hygiene & Safety | Open vessels risk contamination; manual handling of ingredients poses safety and consistency issues. | Closed, sanitary (SUS304/316) flow path designed to meet food-grade hygiene standards, with automated sanitization. |

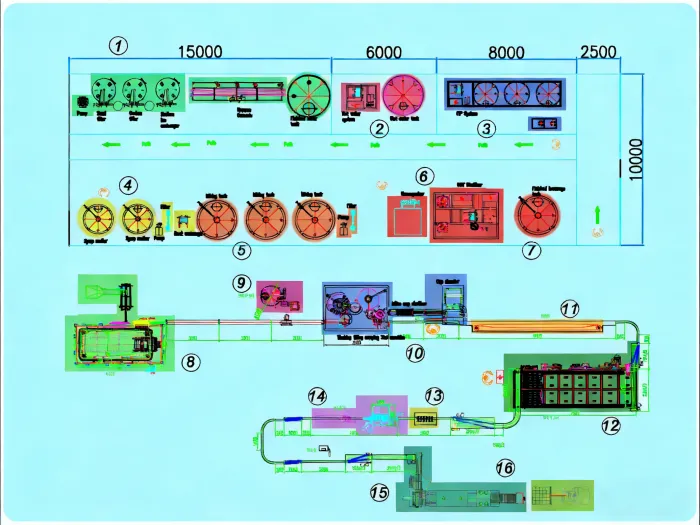

Core Product Showcase: What Makes Perfect Blending Work

The Intelligent Dosing & Proportioning Heart

Absolute precision in every ingredient

Multi-Channel Dosing System: For each ingredient stream (sugar syrup, concentrate, acidulant, preservative) high precision mass flow meters or coriolis flow meters are employed. It offers mass-based dosing, the most accurate way of dosing which is not influenced by temperature or viscosity variations.

Water Flow Control Module: Accept the treated water (RO/Softened) as the base ingredient and control it. With deaeration for best product stability. PLC Recipe Controller: The system’s brain. It stores all recipes and runs each dosing pump according to the recipe norms and it monitors, at real-time, that all ratios are perfectly adhered to.

Advanced In-Line Mixing Technology

Developed Homogeneous Perfection in Second Hands

Static Mixer Bank: A sequence of clean static mixers offers effective, the low shear blending without the use of any moving parts for simple syrup-water mixtures.

Dynamic In-Line Mixer / Homogenizer: For emulsions, dairy products, or any application requiring high speed, immediate mixing. Designed for oil-in-water or powder formulations to be perfectly mixed without air entrapment.

CO2 Injection & Carbonation Chamber: The secret to sparkling wines. CO2 is injected with precision into the cold water / blend stream under the defined pressure in the specialized column to achieve the best dissolution and steady carbonation levels.

Integrated Support & Finishing Modules

From Blend to Finished Product

Sweetwater (Premix) Tank: the premix of syrup and water is blended in a batch process prior to being delivered to the carbonator or filler by a buffer tank.

In-Line Brix & CO2 Monitor: Real-time Quality Assurance. Dynamic Brix (sugar content) and CO2 volume readings are continuously monitored by sensors that notify the PLC, which automatically delivers micro-adjustments to bot ensure that every drop is in spec.

Automated CIP System: A dedicated CIP cycle flushes and cleans the entire blending loop with water, caustic, and acid to assure hygienic conditions and avoid cross batch contamination.

Application

Carbonated Soft Drinks (CSD): Complete syrup dosing, deaerated water blending, and CO2 carbonation systems for colas, lemon-lime, and sparkling waters.

Juices & Nectars: Precision blending of concentrates, purees, water, and sweeteners. Low-shear mixing options to preserve pulp integrity and fresh flavor.

Ready-to-Drink (RTD) Tea & Coffee: Accurate blending of extracts, sweeteners, and pH-adjusting agents. Often integrated with liquid nitrogen dosing for shelf-stable products.

Enhanced & Functional Waters: Precise micro-dosing of vitamins, minerals, electrolytes, and subtle flavors into purified water.

Beer & Cider (Post-Filtration): Accurate blending of deaerated water for high-gravity dilution, and CO2 adjustment to precise target levels.

Dairy & Plant-Based Drinks: Homogenizing systems for smooth integration of proteins, fats, sweeteners, and stabilizers.

Technical Specifications & Capacities

| System Parameter | Standard Range / Specification | Key Feature / Benefit |

|---|---|---|

| System Capacity | From 500 LPH pilot systems to 25,000+ LPH full production lines. | Modular design scales with your growth. |

| Dosing Accuracy | ±0.5% of set point for each ingredient (using Coriolis meters). | Guarantees recipe fidelity and cost control. |

| Carbonation Control | CO2 Volumes range: 1.0 to 5.0+ Vols. Stability: ±0.1 Vol. | Perfect, consistent fizz every time. |

| Brix Control Accuracy | ±0.1°Brix with in-line monitoring and feedback control. | Ensures sweetness and mouthfeel are always on target. |

| Materials in Contact | AISI 304 & 316L Stainless Steel, sanitary fittings, FDA-compliant seals. | Guarantees product purity and easy cleaning. |

| Control Interface | Color Touchscreen HMI + Industrial PLC. Data logging and recipe management. | User-friendly operation, full traceability. |

| Integration | Seamless interface with upstream Water Treatment and downstream Filling machines. | Creates a unified, efficient production line. |

we’re here to all your questions

Why is a water analysis report mandatory for a quote?

It ensures accurate design. Guessing contaminants can lead to under- or over-sized systems, risking failure or extra cost.

What is included in your 18-month guarantee?

Covers material and workmanship defects for core equipment, with FAT, installation supervision, commissioning, and operator training.

Can you handle seawater or high-TDS brackish water?

Yes. We use specialized RO membranes and energy recovery devices, with critical pre-treatment for challenging sources.

How do I maintain the system?

Systems have automatic backwash and CIP cycles. Manuals and lifetime technical support are provided. Consumables have predictable lifecycles.

What makes your RO system different?

Top-tier membranes plus proper pre-treatment, optimal pumps, and intelligent controls ensure stable performance and lower total cost of ownership.