Bottle Blowing Machine

High-Speed, Reliable Bottle Blowing Machines for Your Production Line

You are here: Home » Bottle blowing machine

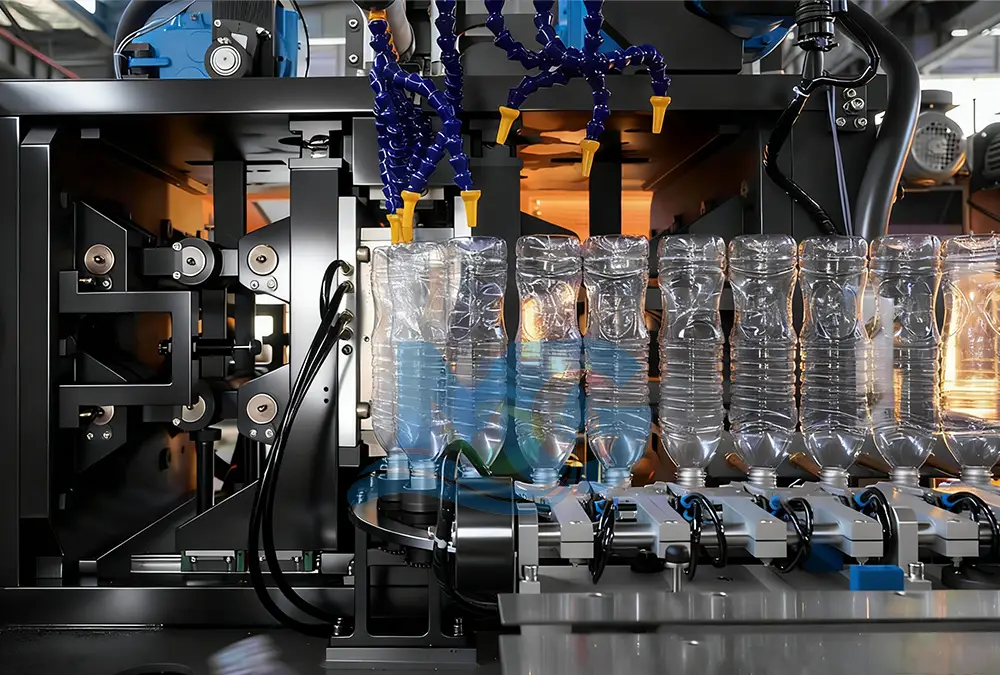

Complete Blow Molding and Packaging Solutions

MG Machinery offers full line automation solution from preform handling, blow molding, filling to final packaging. With strong system integration capability, MG is able to offer dependable customized turnkey solutions for numerous applications of beverage and liquid packaging.

MG understands that easy operation and maintenance is the most important factor for our customers, therefore MG uses the advanced technology of Western Europe to develop the friendly, high automating equipment. This guarantees stable and efficient operation in the long run and lets customers feel at ease.

Essential Spare Services & Auxiliary Equipment

We strongly recommend keeping these critical spares and systems operational:

| Component | Function & Benefit | Consequence of Neglect / Lack of Proper Treatment |

|---|---|---|

| Air Compressor | Provides compressed air for blowing and mechanical actions. | Inconsistent blowing pressure, leading to defective bottles (thin walls, deformation). Reduced machine speed and action reliability. |

| Air Dryer & Filter | Cools and dries compressed air, removing moisture and oil. | Poor bottle quality (haze, water spots). Increased wear and corrosion of pneumatic valves and cylinders, leading to frequent breakdowns and high spare part costs. |

| Industrial Chiller | Cools the molds precisely, maintaining optimal temperature. | Inability to run 24/7. Molds overheat, causing long cycle times, bottle sticking, and crystallization. Final bottles may have flaws and weak structural integrity. |

Our Core Products: Precision That Performs

J Series Linear Bottle Blowing Machine (Ideal for Flexibility)

This all purpose solution is perfect for mid-volume manufacturing and applications involving a large number of bottle design variations. The preforms are allowed to proceed in a straight line from heating to blowing and ejection stations under the linear arrangement, which makes the process easy, flexible and convenient.

The J2 Linear Machine is made for maximum flexibility with fast mold change overs and excellent shape and size adaptability. The dual cavity system has a theoretical capacity of 1,200-1,300 bottles per hour with maximum bottle size up to 5 liters, making it an excellent choice for entrepreneurs, R&D or short to medium production runs

KM-A4 Rotary Automatic PET Blowing Machine (Built for High Output)

Built for heavy-duty continuous operation, the system provides excellent stability and reliability for long runs. The rotary carousel system allows for continuous high-speed bottle blowing, making it suitable for high volume production environments where efficiency and uniformity are crucial.

MG-A4 Rotary Machine has superior capacity and energy efficiency, its production rate is between 3,200 – 4,000 bottles per hour according to bottle design. With four cavities, it is the right solution for high-volume beverage producers, bottled water companies, and similar liquid packaging businesses.

Application Areas: Bottles We Help Create

With our machines, you can form the container quality that you want for your target industry. In the beverage industry, they are particularly popular for water, carbonated soft drink, juice and tea bottles. For Sauce, condiments and Cooking Oil packaging, they are a trusted name delivering reliable results for food and edible oils.

They are also relied upon in household, chemical and personal care products ( detergent, cleaning products, shampoo, lotion, cream and sanitizer bottles ) In fact it’s very difficult to find a market we don’t have an application. Plus, our system solutions enhance pharmaceutical and medical use with reliable external packaging and liquid containers that satisfy the most rigorous quality requirements.

Technical Specifications at a Glance

Compare our two flagship models to find your perfect match.

| Parameter | J2 Linear Machine | KM-A4 Rotary Machine |

|---|---|---|

| Machine Type | Linear | Rotary |

| Max Output (Theoretical) | 1,200 – 1,300 BPH | 3,200 – 4,000 PCS/H |

| Number of Cavities | 2 | 4 |

| Max Bottle Volume | 5 Liters | Customizable (Typical range up to 2L for high-speed) |

| Max Bottle Height | 400 mm | 350 mm |

| Heating Power | 48 KW | Adjustable Infrared System |

| Installed Power | 51 KW | 49 KW |

| Avg. Power Consumption | ~35.7 KW | ~14 KW (Highly Efficient) |

| Blow Air Pressure | 25-35 kg/cm² | 3.0 MPa (≈30 kg/cm²) |

| Cooling Water Flow | 50 L/min | 15 L/min |

| Machine Footprint | 4.7m x 1.6m | ~1.9m x 1.85m |

| Key Advantage | Flexibility, Quick Changeover | High Speed & Efficiency |

(Explore our full machine specifications sheet for more details.)

Blow Molding Technology & MG’s Performance Advantage

Blow molding forms bottles by expanding a heated thermoplastic preform in a closed mold. MG bottles the whole process to precision heat, stretch, and blow, with a linear and movie version that bring consistency to bottle geometry, high productivity and reliable production.

MG’s technological superiority derives in part from sophisticated PLC, fully servo driven positioning and stretching system and an intelligent IR heating system that ensures a homogeneous temperature field and minimal scraps. Operation and monitoring are simplified by a friendly HMI, while stable, safe and long-term high-performance operation is guaranteed by strong mold clamping, high quality pneumatic components and separable air circuits.

One Partnership, Lifetime Support

We don’t just sell machines—we establish partnerships that evolve with your needs and growth potential. Whether installation and commissioning or daily maintenance, our service team supports your equipment from the first day to ensure a trouble-free operation.

Our dedication extends over the whole lifespan of your production line, including remote video engineering support to resolve issues quickly, a training kit with videos and manuals, and technical consultation for life. This combination of support helps reduce downtime and build lasting confidence in your investment.

we’re here to all your questions

Are your machines easy to operate for new users?

Absolutely. Our focus is on user-friendly design. With the intuitive Human-Machine Interface (HMI), comprehensive manuals, and our remote training videos, operators can become proficient quickly.

What kind of after-sales support do you offer?

We provide a robust package: 1-year warranty on parts, lifetime technical support, 24/7 remote assistance via video, and readily available spare parts recommendations to keep your line running smoothly.

What about energy consumption?

Our machines are designed for efficiency. The KM-A4 rotary machine, for example, has a very low actual power consumption (~14KW) thanks to servo technology and optimized systems.

Can you provide molds for our specific bottle design?

Yes. As a complete system provider, we can connect you with reputable mold makers or offer guidance on mold specifications for your bottle design.

What is the lead time for a machine?

Standard model lead times vary. Contact us with your requirements for an accurate timeline and quotation.