Prefrom/Cap Injection Machine

High-Efficiency PET Preform & Cap Injection Molding Machines

You are here: Home » Prefrom/Cap Injection Machine

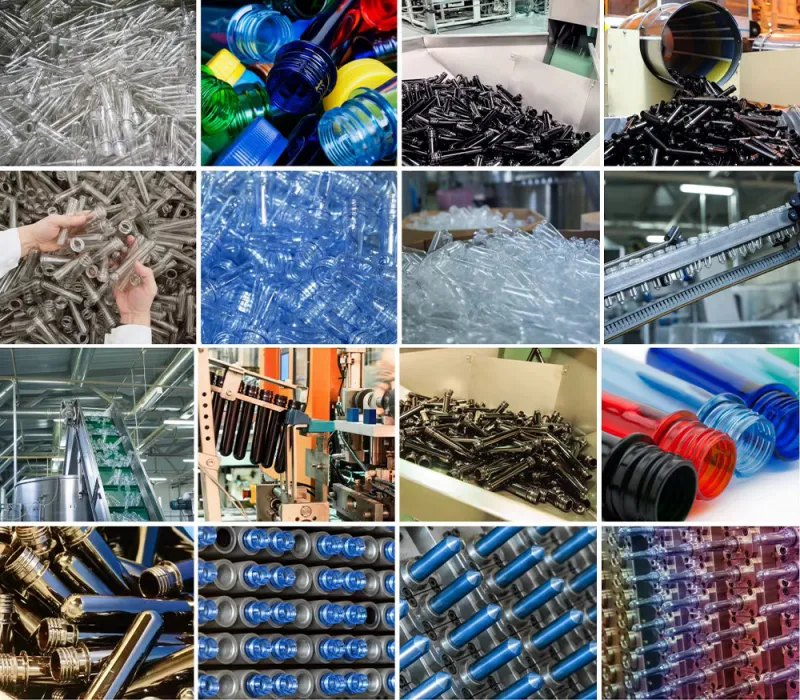

The Smart Core of PET Bottle Production

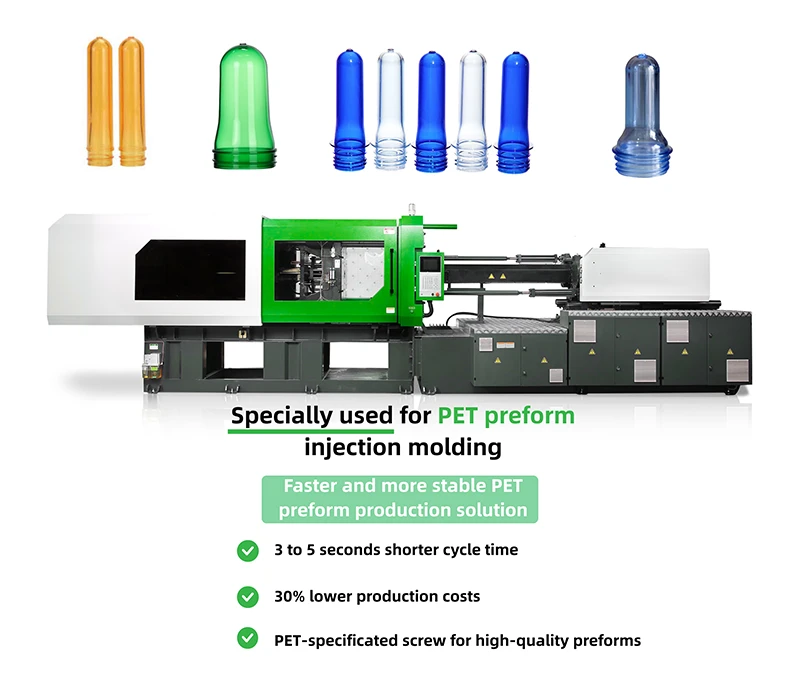

Unlock superior bottle quality at the source with our next-generation PET preform injection molding systems. Designed for high output and exceptional consistency, these machines deliver stable, repeatable precision to ensure every preform meets the strictest quality standards.

Powered by a high-performance servo drive system, the HD Series provides 50% greater driving force, up to 30% faster cycle times, and 30% lower energy consumption. Seamlessly integrated into blow molding operations, it forms a reliable, high-volume foundation from preform to cap.

Precision Preforms, Better Bottles

The quality of your final container is determined at the preform stage. An inefficient or inconsistent injection process creates downstream bottlenecks, material waste, and quality defects that compromise your entire production line.

The High Cost of Inefficient Preform Production

| Production Aspect | With Our HD Series Injection Machine | With Standard/Outdated Equipment | Impact on Your Business |

|---|---|---|---|

| Energy Consumption | 30% reduction in electricity via advanced servo-hydraulic system. Energy is used on-demand, not wasted. | High constant energy draw from traditional hydraulic systems, regardless of machine activity. | Significantly lower operational costs, improving margin per preform and reducing carbon footprint. |

| Cycle Speed & Output | 30% faster cycle times due to superior servo drive force and precision. Maximizes shots per hour. | Slower, inconsistent cycles limit maximum output and create a bottleneck for your blowing lines. | Higher production capacity from the same footprint. Meets demand without adding extra machines. |

| Preform Quality & Consistency | Special PET-feeding screw ensures perfect plastification, uniform melt temperature, and superior material properties. | Risk of uneven heating, degradation, or weak spots, leading to blowing failures and bottle defects. | Dramatically lower scrap rates (<0.5%). Produces strong, consistent preforms for optimal bottle clarity and strength. |

| System Stability & Uptime | Robust construction with precision components designed for 24/7 operation. Minimal maintenance intervals. | Frequent breakdowns, temperature fluctuations, and alignment issues cause unplanned downtime. | Predictable, continuous production. Protects your supply commitments and maximizes asset utilization. |

| Total Cost of Ownership | Higher initial efficiency yields rapid ROI through energy savings, higher output, and reduced waste. | Lower upfront cost offset by perpetually high energy bills, maintenance costs, and quality penalties. | Superior long-term investment. Our machines are engineered for profitability over a decade or more. |

Built for High-Performance Production

Our systems are designed to work in harmony—depalletizers feed your line, and palletizers close it—creating a continuous, automated loop.

Core Product Showcase: MG Series High-Performance PET Injection Systems

The MG Series has the capacity to grow with your business needs, allowing you to choose from a broad spectrum of PET preform injection machines for application from the flexible mid-volume to the high-volume, high-complexity production. Each model strikes the right balance of accuracy, efficiency and durability.

MG290PET – Compact Power, Proven Performance Built for the growing manufacturer and specialized line of products, the MG290PET accommodates molds of up to 32 cavities providing consistent, high precision within a space saving footprint. Producing up to 7,200 preforms per hour, this is the first choice of beverage manufacturers and bottle converters for reliability, nonstop performance of classic shapes.

MG330PET – Versatile Performance for Scalable Production

The MG330PET is tailored to meet increased production requirements and deliver consistent output quality, Multi-Axis stable. It is a dependable core-machine for the beverage producer looking to grow in the challenging beverage markets.

Designed for 48-cavity molds, the MG330PET offers maximum efficiency and profitability. With a capacity of 10,800 preforms per hour, it caters for medium to large scale producers of water, carbonated soft drinks and juices bottles who are thinking of growing in a scalable manner without losing the consistency of quality on preforms.

MG390PET – Maximum Output for High-Volume Production

The MG390PET is tailored for high-hard output in large scale production environments in which availability, and efficiency are paramount. It is the highest ranked model in the HD Series, and delivers the ultimate performance for mass production.

Suitable for 72-cavity molds, the MG390PET comes with the series’ most powerful servo drive system and the best output-to-energy equatio. Delivering a production of more than 13,000 preforms per hour, it suits perfectly for beverage majors and professional preform suppliers who put their focuses on maximum throughput and minimum cost per unit.

Application Spectrum: One Platform, Multiple Industries

Our PET preform injection molding machines provide a solid base for numerous types of containers – and not only beverage containers. Built for precision and flexibility, they can be matched to a variety of product and packaging specifications.

Whether it’s water, carbonated beverages, juice or tea, or even sauce, edible oil, detergent, cosmetic or pharmaceutical packaging, our machines ensure reliable, compliant output. They are high-quality, well-crafted products and also for specialty applications such as wide-mouth jars, thin walls containers as well as customized preform shapes giving manufacturers the opportunity to explore new frontiers.

Technical Specifications Comparison

| Parameter | Unit | HD290PET | HD330PET | HD390PET |

|---|---|---|---|---|

| Mold Cavities (Typical) | Cavities | 32 | 48 | 72 |

| Theoretical Output | pcs/h | 7,200 | 10,800 | 13,000 |

| Preform Weight Range | g | 10 – 18 | 10 – 18 | 10 – 18 |

| Injection Volume | cm³ | 1,325 | 2,268 | 3,177 |

| Opening Stroke | mm | 610 | 660 | 710 |

| Space Between Tie-Bars | mm | 630 x 630 | 680 x 680 | 730 x 730 |

| Mold Thickness (Min-Max) | mm | 230 – 630 | 250 – 680 | 280 – 730 |

| Hydraulic Ejection Force | kN | 113 | 181 | 181 |

| Ejector Stroke | mm | 165 | 170 | 200 |

| Core Efficiency Tech | Servo Drive System | Servo Drive System | Servo Drive System |

The Complete Preform Production Ecosystem: One-Stop Integration

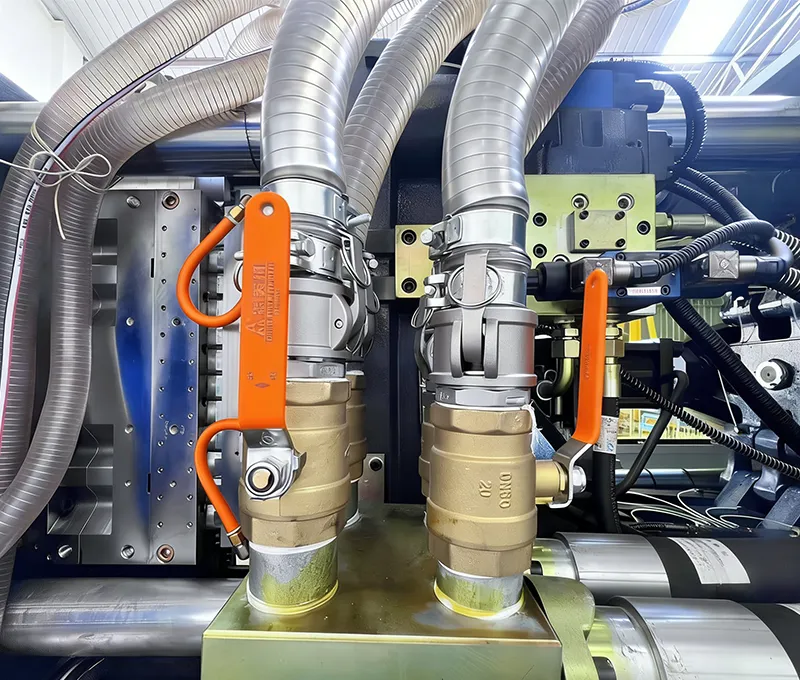

A high output preform line is not only the injection molding machine. We provide the right solution to meet your application challenges with everything you need for stable, efficient production from auxiliary to auxiliary.

From dehumidifying dryers and automated loading systems to exacting mold temperature control, material recyclers, and core utilities such as air compressors and overhead cranes, each element is chosen for you to integrate smoothly. The end result is a lean, dependable production system that delivers high quality, great up-time and long-term cost effectiveness.

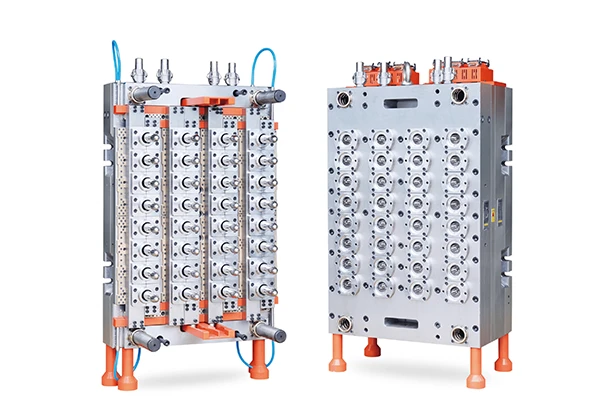

Built to Last: Premium PET Mold Technology

And our quality requirements extend even to the molds that make every preform. We work with the best mold makers or directly provide high-performance mold solutions, and guarantee that each mold unit meets the highest quality standards in durability and precision.

Made of S136, M333 or HRC treated alloys, our molds are designed for 3–5 million shots with maintenance. Machining at the micron level of cores, cavities and neck rings ensures interchangeability, uniform heat extraction is ensured by adapted cooling channels for the fastest heat removal possible for the maximum productivity.

we’re here to all your questions

How do I choose the right machine size and cavity number?

Base it on target output, preform weight, and available utilities. HD290PET (32 cavities) → ~7,200 pcs/h, HD330PET (48 cavities) → ~11,000 pcs/h, HD390PET (72 cavities) → 13,000+ pcs/h. Our engineers can recommend the most cost-effective configuration.

What is the delivery timeline?

Standard machines: 35–45 days. Custom molds: 45–60 days. Detailed schedules provided, expedited delivery available.

How does the servo system save energy?

Servo-driven hydraulics provide power on-demand for each cycle phase, using only the energy needed and eliminating idle waste—up to 30% savings.

Is training and support provided?

Yes. Remote and on-site training, full manuals, and lifetime technical support via phone, video, and email are included.

Can you supply a complete production line?

Yes. Turnkey solutions include all auxiliary equipment (dryer, loader, chiller, crusher, mixer, compressor) fully integrated for single-point responsibility.