Equipment maintenance

MG ProActive Maintenance: Maximize Uptime, Minimize Risk

You are here: Home » Equipment Maintenance

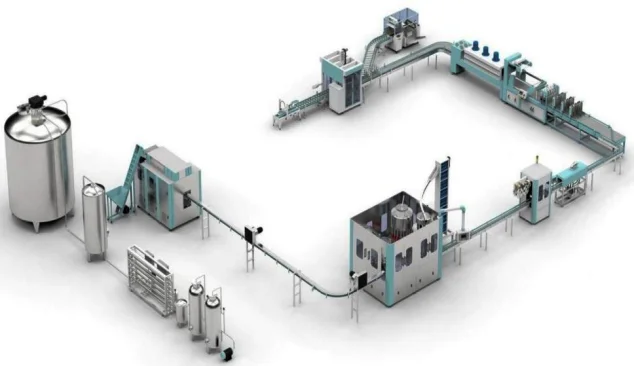

Beyond Repairs — Built for Long-Term Performance

Reactive maintenance is costly and disruptive. MG ProActive Maintenance transforms your approach from fixing failures to preventing them.

Our data-driven, tiered maintenance programs are designed to extend equipment lifespan, optimize performance, and safeguard your production output. Partner with us to move from unpredictable downtime to predictable, planned productivity.

Maintenance Costs: Fixing Problems vs. Preventing Them

Choosing a maintenance strategy directly impacts your bottom line. Here’s a clear comparison:

| Aspect | Proactive Maintenance (MG Standard) | Reactive / “Run-to-Failure” Approach | Business Impact |

|---|---|---|---|

| Cost Structure | Planned, predictable expenses. Lower frequency of major repairs. | Unpredictable, high-cost emergencies. Includes collateral damage and rush fees. | Budget control vs. financial surprises. Proactive care can reduce total costs by up to 40%. |

| Equipment Uptime | Maximized. Scheduled during planned stops. Achieves over 95% operational availability. | Minimized. Failures cause unscheduled, extended downtime during production runs. | Missed shipments vs. reliable output. Directly impacts revenue and customer trust. |

| Parts & Labor | Uses genuine MG parts during scheduled service. Efficient, planned labor. | Often requires urgent, premium-priced parts and overtime labor. | Higher long-term cost of ownership. Increased risk of using non-genuine parts. |

| Equipment Life & Value | Extended lifespan. Maintains original performance specs and resale value. | Accelerated wear and tear. Leads to premature failure and diminished asset value. | Protects capital investment. An asset versus a liability. |

| Safety & Quality | Consistently high. Regular calibration ensures fill accuracy, seal integrity, and operator safety. | Compromised. Drifting parameters lead to product waste, quality rejects, and safety hazards. | Brand protection vs. risk of recall. |

Pick the Maintenance That Works for You

Essential Care Plan

For new machines under warranty or lines running smoothly with standard operations.

This package includes remote monitoring support with MG iCare setup, giving you basic performance dashboards. Your team also gets digital inspection checklists to follow scheduled maintenance steps easily.

Plus, we provide an annual health check with an on-site MG technician for system calibration and performance review, along with priority access to spare parts — including a 10% discount on preventive maintenance kits.

Performance Plus Plan

For high-use lines (running 2+ shifts) or those producing multiple product types.

This tier includes everything in Tier 1, plus bi-annual on-site visits for deep cleaning, mechanical adjustments, and wear part replacements. We also handle consumables management, automatically sending pre-configured maintenance kits before each service.

Your team gets an operator training refresh with annual access to updated online modules, and we provide Predictive Analytics Lite, analyzing machine data trends with quarterly reports and actionable recommendations.

Total Care Partnership

For mission-critical, 24/7 production lines or facilities without a dedicated maintenance team.

This tier includes everything in Tier 2, plus unlimited remote support — 24/7 access to MG engineers via phone or live video for diagnostics. We also provide quarterly on-site visits covering full service, including auxiliary equipment like conveyors and air systems.

Your line benefits from full predictive maintenance using IoT sensor data to catch potential issues 2–4 weeks in advance, along with a guaranteed uptime SLA, giving defined response times and performance-backed uptime assurances.

The MG ProActive Maintenance Process

Thorough Assessment & Baselining – We start with a full audit of your equipment, reviewing current condition, performance history, and past issues to set a clear baseline.

Tailored Planning & Expert Execution – Based on the audit, we recommend a maintenance plan (Tier 1, 2, or 3) with a schedule that fits your production. Certified MG technicians carry out all work using calibrated tools and genuine MG parts.

Digital Tracking & Continuous Improvement – Every service is logged in your secure MG iCare Portal, including work done, parts used, and performance metrics. We review results with you quarterly to refine the plan and uncover new optimization opportunities.

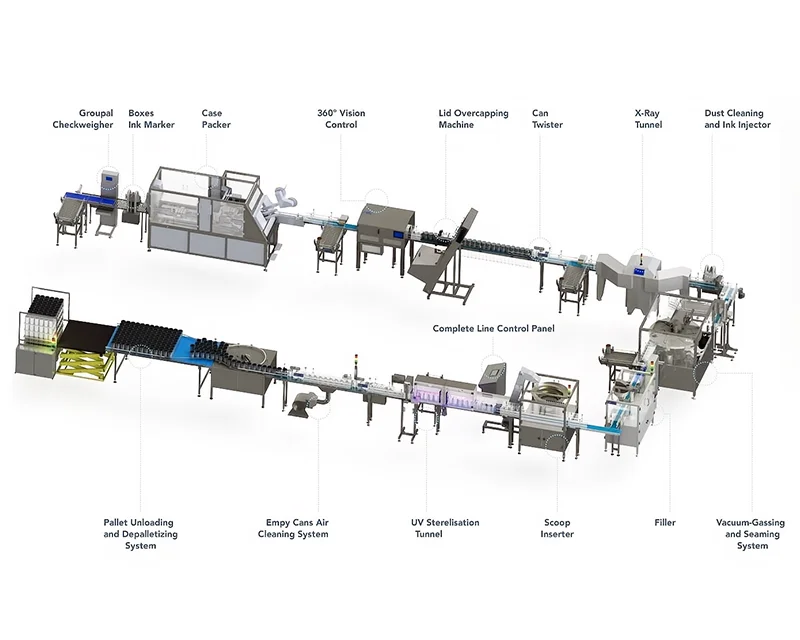

Core Maintenance Services in Detail

Preventive Maintenance (PM) – Routine tasks to keep machines from breaking down.

Example: Lubricating capper heads, checking and replacing bottle neck cushions and conveyor chains, cleaning filling valves and rinsing nozzles.

Predictive Maintenance (PdM) – Using data to catch problems before they happen.

Example: Vibration checks on motor bearings, thermal scans of electrical panels, analyzing solenoid valve response trends.

Corrective & Performance Maintenance – Fixing issues and fine-tuning for efficiency.

Example: Replacing worn capper jaws, resealing filling valves, recalibrating sensors, adjusting settings for faster changeovers, optimizing air pressure, and tuning fillers to reduce oxygen pickup.

we’re here to all your questions

Can we handle maintenance ourselves?

Yes. Tier 1 tasks are covered by Online Academy training. Tier 2/3 services should be done by MG technicians.

How does predictive maintenance work?

The iCare Gateway collects PLC and sensor data and analyzes trends. Alerts are sent before failures occur.

What if a critical part fails under a plan?

Tier 2/3 plans cover labor. Parts are discounted and shipped with priority.

How do we start a maintenance assessment?

Request a free remote assessment. We review your line and provide recommendations within one week.

Is certification provided?

Yes. A downloadable MG Certificate is issued after passing each module quiz.

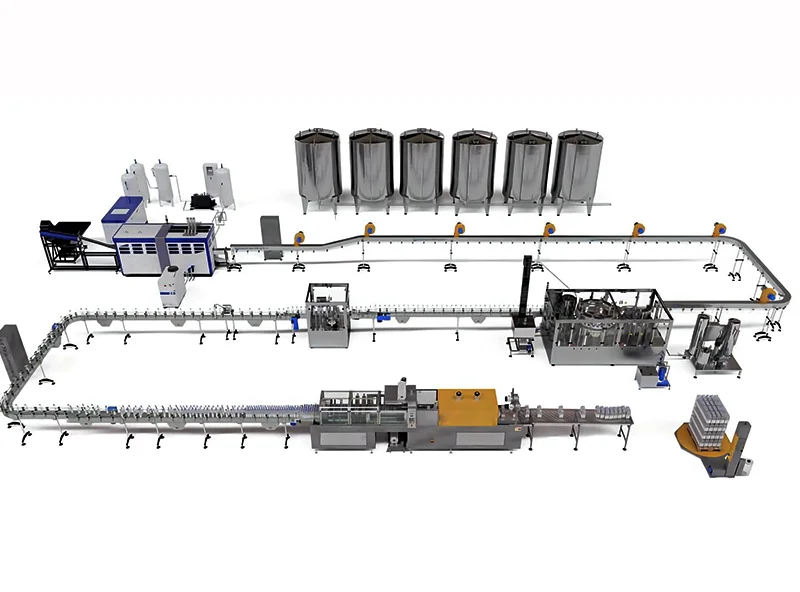

A Filling Solution That Doubles Efficiency

— Proven by 100+ Factories

Tell us your product, and we’ll match you with the most suitable filling solution.