Turnkey Project

MG Turnkey Solutions: Your End-to-End Beverage Production Partner

Your vision, delivered in a bottle

Stop managing a dozen suppliers and navigating complex integrations. MG delivers true turnkey beverage production lines—from initial concept to bottles rolling off the line. We take single-point responsibility for your entire project: consultation, design, manufacturing, installation, commissioning, and lifelong support. Whether it’s water, juice, tea, or carbonated drinks, we transform your blueprint into a fully operational, profitable facility.

The Burden of Piecemeal vs. The Power of Turnkey

Assembling a line from multiple vendors is fraught with risk, delay, and hidden cost.

| Challenge | The Piecemeal Approach (Multi-Vendor) | The MG Turnkey Solution | Your Guaranteed Outcome |

|---|---|---|---|

| Project Leadership | You become the de facto project manager, coordinating between disjointed suppliers. | MG is your single point of contact and responsibility. We manage all interfaces and integration. | Peace of mind. One contract, one team, one unified goal: your success. |

| System Compatibility | Risk of mechanical, electrical, and control mismatches between machines. | Seamless integration by design. Every component, from blow molder to palletizer, is engineered to communicate and synchronize perfectly. | Optimal line efficiency (OEE) with no bottlenecks or finger-pointing between suppliers. |

| Cost & Timeline Control | Unpredictable change orders, scope creep, and delays as vendors blame each other. | Fixed price, fixed timeline contract. We bear the risk of integration, ensuring the project stays on budget and schedule. | Financial predictability and faster time-to-market, accelerating your ROI. |

| Performance Warranty | Individual machine warranties; no one is accountable for overall line performance. | A single, comprehensive performance warranty for the entire line’s output, efficiency, and quality. | Guaranteed output of saleable product meeting your specifications. |

| Long-Term Support | Multiple service contacts, incompatible spare parts, and complicated diagnostics. | Lifetime support from one team. Unified maintenance, genuine parts for all components, and holistic line diagnostics. | Maximum uptime with simplified, long-term operational care. |

With you every step of the way

Strategic Consultation & Feasibility

We begin by understanding your business, not just your technical specs.

Market & Product Analysis: Aligning production capabilities with your target market (still, sparkling, sensitive products).

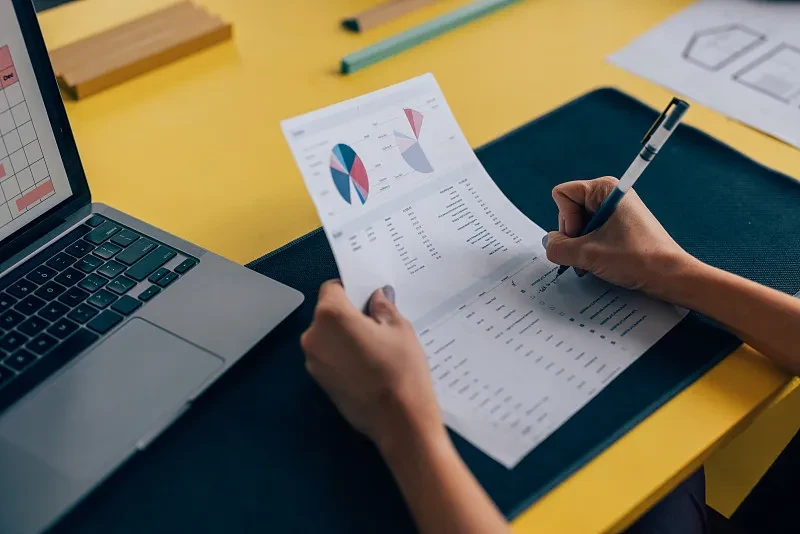

CAPEX/OPEX Financial Modeling: A transparent Cost & Profitability Analysis forecasting your operational costs and breakeven point.

Master Planning: Defining line capacity, future expansion pathways, and facility layout advisory.

Collaborative Design & Engineering

- Process Flow Design: Determining the exact sequence: PET Preform Injection -> Blow Molding -> Rinsing -> Filling (Hot/Cold/Carbonated) -> Capping -> Labeling -> Packaging -> Palletizing.

Layout diagram& Factory Simulation: Virtual modeling of the entire line to optimize workflow, maintenance access, and operator safety before a single machine is built.

Core Technology Selection: Specifying the right technology for each stage (e.g., Isocratic Filling Valves for carbonation, electromagnetic flowmeters for juice, aseptic barriers if required).

Integrated Manufacturing & Quality Assurance

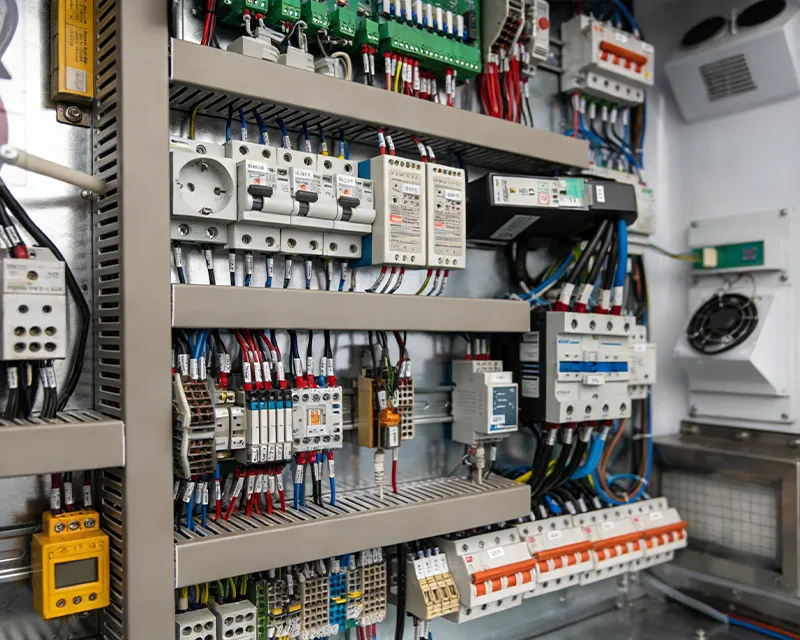

- Unified Control System Architecture: All machines built around a common PLC/HMI platform (Siemens/Rockwell) for a single operator interface.

Pre-Assembly & FAT (Factory Acceptance Test): Key sections are assembled and tested together at our facility. You’re invited to witness the line running under load before shipment.

Single-Source Component Quality: Critical components like Solenoid Valves, Conveyor Chains, and Filling Valves are sourced to a unified standard, ensuring reliability and spare parts commonality.

Seamless Installation & Commissioning

We bring the blueprint to life in your facility.

Project Management On-Site: A dedicated MG project manager oversees every detail of installation, civil work, and utility hook-ups.

SAT (Site Acceptance Test) & Performance Run: We commission the line, fine-tune it with your actual products, and achieve the guaranteed performance metrics.

Comprehensive Training: We train your production, maintenance, and quality teams on the entire integrated system, not just isolated machines.

Lifelong Optimization & Support

Our partnership continues long after the line is operational.

Performance Monitoring: Remote connectivity (MG iCare) allows us to monitor line OEE and preemptively identify issues.

Holistic Spare Parts Program: One-stop access to genuine parts for every component on the line.

Continuous Improvement Reviews: Annual reviews to discuss optimization, product changes, and capacity expansion.

Our Line Expertise by Beverage Category

We don’t offer generic solutions. Our engineering is tailored to the specific demands of your product.

| Beverage Type | Core Technical Focus in MG Turnkey Design | Key Delivered Outcome |

|---|---|---|

| Purified & Spring Water | High-speed, low-contamination design. Emphasis on rinsing nozzle efficiency, ozone injection integration, and minimal energy consumption per bottle. | Lowest cost-per-bottle production with crystal-clear quality. |

| Juices & Sensitive Drinks (NFC, Tea) | Oxygen-scavenging technology, deaeration systems, and hygienic design to preserve flavor and vitamins. Compatibility with hot fill or aseptic processing. | Extended shelf life, preserved natural taste, and brand integrity. |

| Carbonated Soft Drinks (CSD) | Precision isobaric filling valves to maintain CO₂ levels. Robust carbonation and mixing systems. High-pressure handling capabilities. | Perfect fizz retention, consistent brix-to-carbonation ratio, and zero flat bottles. |

| Functional & Viscous Beverages | Customized filling valve sleeves and piston fillers for precise dosing of pulpy or syrupy products. Specialized cap handling for sport caps. | Accurate fill levels for premium products and leak-proof sealing of complex closures. |

The MG Difference: More Than a Supplier, Your Production Partner

Single-Contract Simplicity: One agreement covering everything, eliminating hidden costs and complexity.

Performance-Guaranteed Outcome: We contractually guarantee output, speed, and efficiency.

Future-Proof Design: Lines are designed with modularity for easy capacity upgrades or new product integration.

Global Success Portfolio: From 5,000 BPH boutique spring water lines to 72,000 BPH integrated CSD facilities.

we’re here to all your questions

Can we handle maintenance ourselves?

Yes. Tier 1 tasks are covered by Online Academy training. Tier 2/3 services should be done by MG technicians.

How does predictive maintenance work?

The iCare Gateway collects PLC and sensor data and analyzes trends. Alerts are sent before failures occur.

What if a critical part fails under a plan?

Tier 2/3 plans cover labor. Parts are discounted and shipped with priority.

How do we start a maintenance assessment?

Request a free remote assessment. We review your line and provide recommendations within one week.

Is certification provided?

Yes. A downloadable MG Certificate is issued after passing each module quiz.

A Filling Solution That Doubles Efficiency

— Proven by 100+ Factories

Tell us your product, and we’ll match you with the most suitable filling solution.