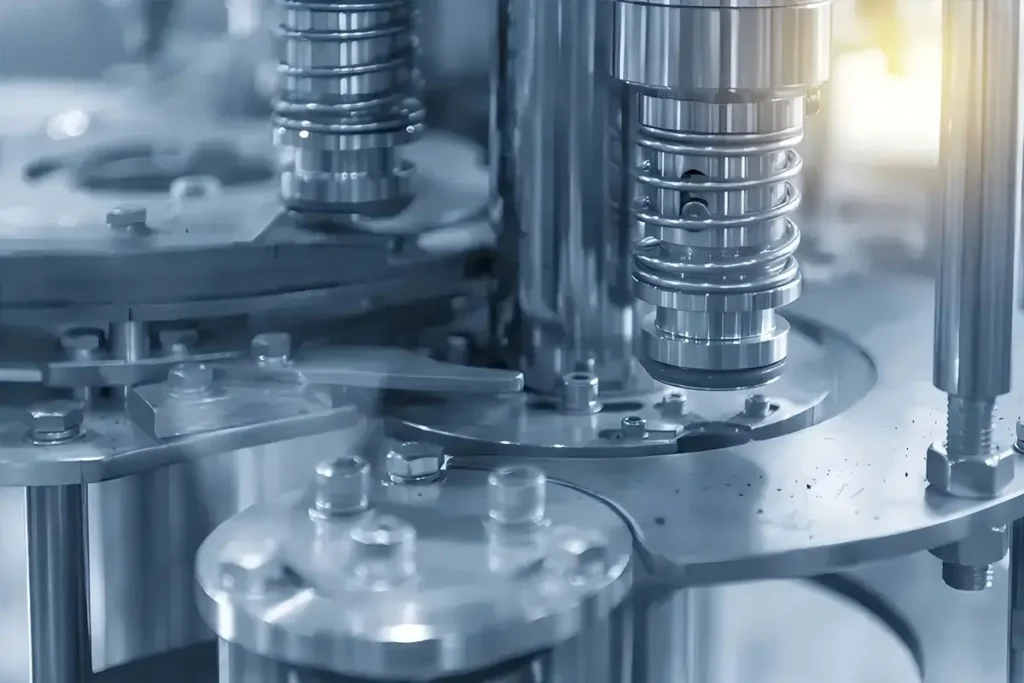

Blowing filling capping combiblock machine

A blowing-filling-capping combiblock machine is an integrated production system used in the packaging industry, especially for liquid products like water, juice, soft drinks, oils, or dairy. It combines three processes in one line

You are here: Home » Blowing filling capping combiblock machine

From preform,

to filled products

The combiblock filling machine or blowing filling capping combi block machine which is suitable for bottle water production line. It has the merits of high working efficiency, large output, and energy saving, space saving as well as cost saving. The capacity can be from 12,000 BPH to 54,000 BPH, as customized capacity.

With the unique single system for online bottle blowing, water filling and capping, the combiblock provides for extremely stable preform and bottle transfer and offers line energy consumption reduction of 25% or more when compared to traditional separated systems.

MG Machine has blowing-filling-capping combiblock for different outputs solutions. The more popular models are 18,000 BPH, 24,000BPH, 36,000 BPH combiblock water filling machine which are suitable for most medium and large scale bottled water industry.

COMBI-BLOC

WORKING PROCESS

- PREFORM INFEED

- PREFORM HEATING

- BLOWING

- STARWHEEL TRANSFER

- FILLING

- CAPPING

- PRODUCT DISCHARGE

Advantages Of Combi-bloc

Less Space

Higher Earnings

Less Operator

More Reliable Quality

Higher Efficiency

Lower energy consumption

Blowing - Filling - Capping

Bottle Blowing Technology

1.High-Efficiency Rotary Preform Feeder The stable high speed loading is guaranteed by a rotary feeder with continuous rotation. The slimline design means less wear and tear leading to lower maintenance and spare parts costs.

2.Intelligent Heating System Hard Anodized aluminum heating heads Perfect for smooth finish and long life. With the optimized heater spacing, thermal efficiency is enhanced to save 50 – 67% energy while ensuring uniform heating of the preforms.

3.Servo-Driven Mold Clamping The precision linkages of a servo motor provide consistent, accurate clamping force. The drawer style mould permits fast changeovers for enhanced flexibility and minimized downtime.

Water Filling Technology

1.Bottle rinsing uses grippers to hold the neck, enabling quick size changeovers without rinser adjustments. A dedicated washing nozzle cleans the mouth securely, preventing secondary contamination.

2.Precision Filling: Bottles move to the filling station, where a lifting mechanism positions them to open the filling valve. High‑accuracy valves ensure fast, correct fill levels.

Bottle Capping Technology

1.Adjustable magnetic capping system: Capping adopts advanced adjustable magnetic capping technology, capping working is steady and tight without damage to cap.

2.High efficiency cap sorting device: The cap sorting device is installed above the capping part, the cap will be sorted and come into the capping part by cap conveyor. And the cap is sent to the cap sorting device by cap elevator.

we’re here to all your questions

What is a bottle labeling machine?

A bottle labeling machine is used to apply labels onto bottles automatically, ensuring accurate and consistent labeling.

Why choose MG Machinery bottle labeling machine?

MG Machinery provides stable, easy-to-use labeling machines suitable for different bottle sizes and label types.

Who needs a bottle labeling machine?

It is suitable for manufacturers of beverages, food, cosmetics, pharmaceuticals, and chemical products.

How does a bottle labeling machine improve production efficiency?

It reduces manual labor, increases labeling speed, and improves labeling accuracy.

A Filling Solution That Doubles Efficiency

— Proven by 100+ Factories

Tell us your product, and we’ll match you with the most suitable filling solution.