Juice filling machine

This fully automatic PET bottle juice/coffee/tea filling production line integrates rinsing, filling, and capping functions, achieving an accuracy rate of up to 99.8%.

You are here: Home » Juice Filling Machine

Efficient, Intelligent Juice Filling Machine

MG Machinery provides complete solutions for juice filling, from standard juice filling machines, to compact models for the small production to high- output lines for fully automatic systems. Our solutions are tailored to individual production requirements, and ensure a consistent and dependable production.

Adopting micro pressure gravity filling system with high efficient recirculation design, Our PET bottle juice filling machine fill without contact. This prevents secondary contamination and oxidation so the quality does not change. Made with high-quality SUS304 stainless steel and key components under CNC processing, these line are perfect for hot filling juice, pulpy beverages, tea drink and coffee in contemporary beverage factories.

3-in-1 Fully Automatic Juice Filling Machine

The 3 in 1 system integrates bottle rinsing, filling with high precision and capping in one fully automatic machine, which saves floor space and investment cost. It is very flexible and ideal for hot-fill products like juice with pulp, coffee, tea drink and mango juice in heat shrinkable PET bottle.

Based on micro-pressure gravity filling principle with separate air return system, the filling machine reduces exposure of the product to air, avoids oxidation and contamination from outside environment and realizes over 99.8% filling accuracy. Product contact parts and main body are made of SUS304 stainless steel finished to mirror surface for easy cleaning, and CNC processed key parts for long lasting solid performance.

Market and Technology Trends 2025

The juice filling industry is rapidly evolving. Here are the key trends shaping the future:

Focus on Flexibility and Smart Manufacturing

The high-end products now come with Industrial 4.0 intelligent control system, with “one-touch changeover” integrated technology.This allows an automatic adjustment of filling parameters, sterilization temperature, labeling positions by just selecting a pre-set recipe, which reduces changeover time from hours to less than 10 minutes and perfectly meets small-batch, multi-variant production mode.

Breakthroughs in High-Speed Aseptic Filling

There have been fundamental advances and breakthroughs in high-end liquid food aseptic filling equipment in home-country in 2025. The new models achieve a speed of 48,000bph with filling accuracy of ±0.7mL, which gets the international leading level.This technology could be used for all liquid food and multi-packaging materials such as PET and PP.

Data-Driven Management and Traceability

Thelines are modern and feature digital twin simulation for pre-optimization and cloud based platforms for real-time monitoring of more than 100 production parameters. Systems for traceability based on blockchain are being introduced, that will enable transparency in the entire supply chain from orchard to shelf.

Precision Handling of Complex Beverages

For the pulpy or particulate juices (NFC juices or mango juice for example) new generation systems are be based on ” screw pump + piston pump” combination. They provide a pass rate of over 95% for pulp and a filling accuracy of ±1.5%, causing much less damage to the pulp.

Advanced and Sustainable Sterilization Methods

In addition to conventional methods, the new plasma sterilization method is evolving. This enables efficient, low-temperature sterilization in a few seconds without leaving any chemical residues (like hydrogen peroxide), making it a safe and eco-friendly solution for aseptic packaging. With integrated “microwave preheating+UHT”systems, energy savings are also achieved, and a better retention of heat-sensitive nutrients (e.g., Vitamin C).

Application Fields

Our juice bottle filling machine is designed for flexibility to meet diverse production needs:

Diverse Product Filling

Suitable for clear juices, juices containing pulp or particles (e.g., mango juice), nectars, concentrates, tea drinks, and coffee beverages.

Production at Various Scales

From small juice filling machines for start-ups or pilot lines to high-speed fully automatic juice filling machines (with capacities up to 24,000 bottles per hour), we provide complete solutions.

Specific Process Needs

We offer specialized hot juice filling machine models to meet the requirements of products needing hot-fill (pasteurization) processes, perfectly preserving flavor and shelf life.

Technical Specifications

| Item | Specification / Description |

|---|---|

| Machine Type | Automatic Bottled Juice Filling Machine |

| Main Functions | Rinsing, Filling, Capping (Tri-in-One) |

| Suitable Container | Heat-resistant PET Bottles |

| Filling Volume | 300ml – 2000ml (Customizable for juice bottle filling machine needs) |

| Filling Accuracy | ≤ ±0.5% (equivalent to 99.8% accuracy) |

| Rinsing Pressure | 0.2 ~ 0.3 Mpa |

| Power Supply | 3 Phase, 380V/50Hz, 1.5~11.5KW (Juice filling machine price varies by configuration; voltage customization available) |

| Capping Success Rate | Defect rate ≤ 0.2% |

| Main Material | SUS304/316 Stainless Steel |

| Control System | PLC with Touchscreen, User-Friendly |

System Advantages & Features

1. Rinsing System

The air conveyor seamlessly attaches to the bottle dial. Full stainless steel rinse heads with spray-style injection design for highest water savings and superior rinsing results. The stainless steel grippers with food grade plastic pads reduce bottle collision and scratching while washing.

2. Filling System

High accuracy stainless steel filling valves offer fine volume micro-adjustment for steady filling levels. All stainless steel product tanks and parts that come into contact with the product are vacuum polished without dead legs, easy to clean (CIP system optional). Recirculation technology delivers contactless filling, thanks to an efficient recirculation pump.

3. Capping System

Electromagnetic capping heads with torque release are used for stable and reliable capping without causing bottles damage. Intelligent Operation: No cap feeding without bottle; Stop automatically when no bottle. High Cap Success Rate Assures Product Seal Integrity.

4. Complete Line Support

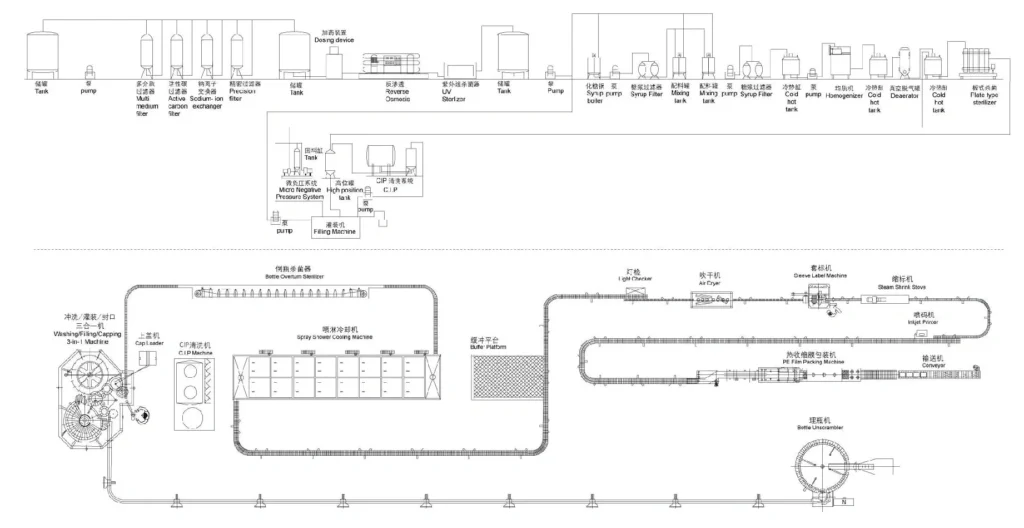

- MG Machine supplies complete systems and production lines in addition to single machines, with line components such as water treatment, blending systems, labelers, packaging systems (film wrappers, case packers), and robotic palletizers, providing a single source solution for our customers.

FAQ

Can this machine handle juices with pulp?

Absolutely. Our equipment is specifically designed with filling systems suitable for products containing pulp or particles, making it an ideal choice for mango juice filling machines and similar applications.

How can I get a specific quote for a juice filling machine?

The juice filling machine price depends on the level of automation, capacity, and configuration (e.g., number of filling heads, inclusion of hot-fill function). Please provide your specific requirements (bottle type, capacity, product characteristics) via the contact form below, and we will provide a tailored quotation.

Can the machine be adjusted for different bottle shapes/sizes?

Yes. Our machines allow for convenient changeover. Adjusting to different PET bottle heights and diameters is achieved by changing a few parts and adjusting parameters on the control panel.

Do you provide after-sales service and technical support?

We provide comprehensive after-sales service, including installation & commissioning, operator training, remote technical support, and timely spare parts supply.

Do you have smaller machines suitable for start-ups?

Yes. We offer various capacity models of small juice filling machines, which are cost-effective and perfectly suited for small-batch production, new product trials, or start-up companies.

Contact Us for Your Custom Solution

If you are looking for reliable juice filling machines for sale or wish to upgrade your production line, please contact us. Our experts will recommend the most suitable juice bottle filling machine or complete line solution based on your product characteristics (e.g., juice type, viscosity) and capacity needs.