After-sale Service

MG 360° After-Sale Service: Your Lifelong Partner for Uninterrupted Production

You are here: Home » After-sale Service

Unmatched Support for Your Investment

Purchasing a production line is the start of a decades-long partnership. At MG, we define world-class After-Sale Service not by reactive fixes, but by proactive care that maximizes your uptime and return on investment.

Our 360° service ecosystem is designed to be an extension of your team, ensuring your MG equipment operates at peak performance, efficiency, and safety throughout its entire lifecycle.

Beyond Warranty. We Partner, Not Just Repair.

True service is about preventing problems, not just solving them. Compare the industry standard to the MG commitment.

| Service Dimension | Typical Supplier Service | MG 360° Service Philosophy | Your Tangible Benefit |

|---|---|---|---|

| Relationship Focus | Transactional. Interaction ends after machine acceptance. | Partnership-Based. We are invested in your long-term productivity and success. | A trusted advisor focused on your operational goals, not just service calls. |

| Problem Resolution | Reactive: “Call us when it breaks.” Long wait times, unclear diagnostics. | Proactive & Predictive: We use data to alert you to issues before they cause downtime. | Dramatically reduced unplanned stops. Issues are resolved during planned maintenance windows. |

| Knowledge Transfer | Basic operational manual. Limited training. | Continuous Empowerment. Multi-level training, certification, and a vast digital knowledge base. | Your team grows more competent and self-sufficient, reducing dependency on external support. |

| Spare Parts Strategy | Slower, centralized supply. Generic part recommendations. | Intelligent Parts Ecosystem. Local hubs, guaranteed-fit parts, and AI-driven predictive inventory. | Faster repairs, lower inventory cost. The right part is available when and where you need it. |

| Performance Goal | Restore basic machine function. | Optimize Overall Line Efficiency (OEE). We analyze data to suggest improvements beyond the original spec. | Continuous improvement in output, quality, and cost per bottle. Your line gets better over time. |

After-Sales Support That’s Got You Covered

Installation, Commissioning & Startup Supervision

On-Site Expert Deployment: Certified MG engineers supervise installation, ensuring perfect alignment and integration.

Performance Validation: We run extensive tests with your actual products to certify the line meets all guaranteed performance parameters (speed, accuracy, efficiency).

Full-System Handover: Formal sign-off only occurs after your team can operate the line independently and achieve target output.

Comprehensive Training & Certification Programs

Tiered Operator Training: From basic controls to advanced troubleshooting, delivered on-site and via the MG Online Academy.

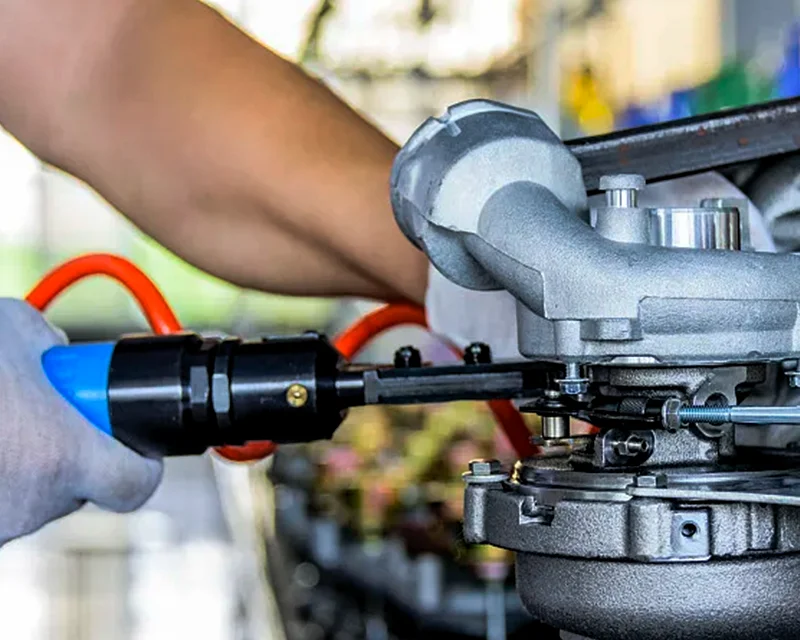

Maintenance Mastery Workshops: Hands-on training for your technicians on preventative maintenance, calibration, and repair of critical systems (e.g., Filling Valve overhaul, Capper Head adjustment).

MG Certified Engineer Program: Advanced program to certify your senior staff, granting them direct access to specialized technical resources and faster support escalation.

Multi-Channel Technical Support

24/7 Global Support Hotline: Immediate access for urgent, line-stopping issues.

Remote Diagnostic Support (MG iCare Connect): Share real-time screen views of your HMI or use our secure IoT gateway for our engineers to perform remote diagnostics, view machine data, and guide your team.

Guaranteed On-Site Response: For issues that cannot be resolved remotely, we have guaranteed response times (e.g., 24, 48, 72 hours) based on your service contract level.

Intelligent Spare Parts & Logistics

Genuine Parts Guarantee: Every part is engineered to original specifications for perfect fit and performance.

Global Logistics Network: Parts stocked in regional hubs (EU, North America, Asia) for expedited shipping.

Smart Parts Identification: Use the MG portal with your machine S/N to view interactive 3D diagrams and order exact components.

Consignment Stock & Kitting: We can hold strategic spare parts at your facility or provide pre-packaged maintenance kits for every service interval.

Planned & Predictive Maintenance Services

Preventive Maintenance (PM) Contracts: Scheduled, regular service visits to inspect, lubricate, calibrate, and replace wear parts (Conveyor Chains, Solenoid Valves, Neck Grippers, seals).

Predictive Maintenance (PdM) via MG iCare: Our IoT system monitors vibration, temperature, and performance trends, generating alerts for potential failures weeks in advance.

Annual Health Check: A comprehensive top-to-bottom inspection and performance review of your entire line, with a detailed report and optimization recommendations.

Performance Optimization & Upgrade Services

- Bottleneck Analysis: We review your line data to identify and resolve throughput constraints.

- Recipe & Parameter Optimization: Fine-tuning machine settings for new products or to improve efficiency (e.g., reducing air consumption, optimizing filler speeds).

- Retrofits & Modernization: Upgrading older MG equipment with the latest technology (new HMI panels, servo drives, energy-saving components) to extend lifespan and capability.

Digital Service Ecosystem (MG iCare Platform)

Centralized Machine Dashboard: Real-time OEE monitoring, alarm history, and production reports.

Digital Work Order Management: Schedule, document, and track all maintenance activities.

Knowledge Base & Documentation: Instant access to the latest manuals, wiring diagrams, and instructional videos for your specific machine models.

Hygienic & Process-Specific Support

CIP/SIP Validation Support: Assistance in validating and optimizing your cleaning-in-place and sterilization cycles.

Microbiological Contamination Investigation: Expert support to trace and resolve sources of product contamination related to equipment.

Compliance Documentation: Support in generating documentation needed for audits (FDA, CE, ISO 22000, etc.).

Decommissioning, Relocation & Trade-In Services

Professional Dismantling & Packaging: When relocating or upgrading, we ensure equipment is properly handled.

Re-installation & Re-commissioning: Setting up your line at a new facility to original performance standards.

Asset Trade-In Program: Offering value for your existing MG equipment when upgrading to newer models.

we’re here to all your questions

Can we handle maintenance ourselves?

Yes. Tier 1 tasks are covered by Online Academy training. Tier 2/3 services should be done by MG technicians.

How does predictive maintenance work?

The iCare Gateway collects PLC and sensor data and analyzes trends. Alerts are sent before failures occur.

What if a critical part fails under a plan?

Tier 2/3 plans cover labor. Parts are discounted and shipped with priority.

How do we start a maintenance assessment?

Request a free remote assessment. We review your line and provide recommendations within one week.

Is certification provided?

Yes. A downloadable MG Certificate is issued after passing each module quiz.

A Filling Solution That Doubles Efficiency

— Proven by 100+ Factories

Tell us your product, and we’ll match you with the most suitable filling solution.