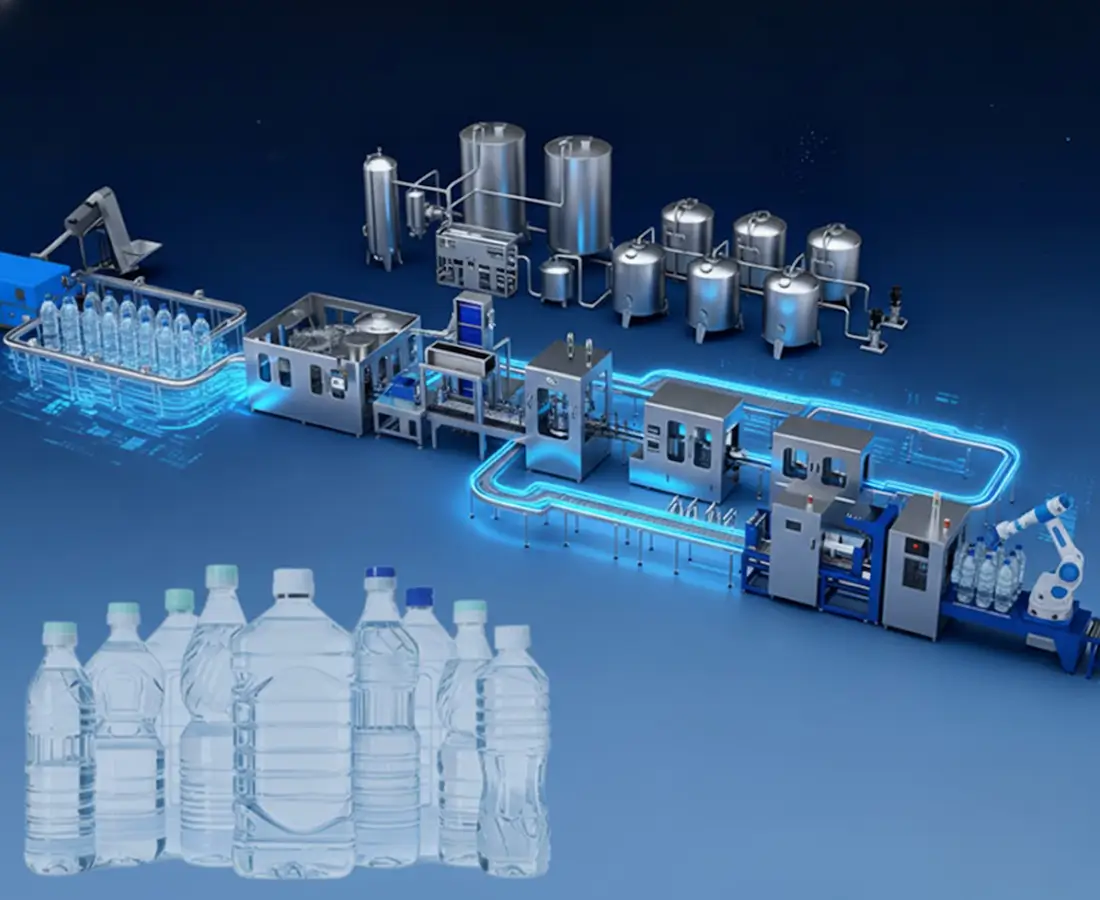

Bottled water production line

A bottled water production line is a series of integrated machines and processes designed to turn raw water into finished bottled water — water filter ,bottle rinsing, filling ,capping ,labeling ,packaging — ready for distribution.

You are here: Home » Bottled water production line

MG Machine offers high-speed mechanical gravity fillers Semi-electronic valve filling, electronic valve filling, flow meter filling, etc.(20–100 valves, 3,000–50,000 bph for 0.5L PET bottles), delivering crystal-clear, contaminant-free still water filling with maximum efficiency, accuracy, and bottle light-weight optimization.

High-speed filling:

The production capacity can reach 2,000 to 30,000 bottles per hour (depending on the model), and the advanced PLC system accurately controls the flow to minimize downtime and ensure stable operation.

Fully automated process:

Made of food-grade stainless steel, it not only ensures product safety, but also improves the durability of the equipment.

Multi-station synchronization:

The equipment adopts an efficient rotary structure design, which supports 8~60 filling heads working at the same time, further improving the overall production efficiency.

CIP cleaning system:

The rotary design supports multiple filling heads working at the same time, greatly improving production efficiency.

Core Advantages

High Capacity

Low energy consumption

Durable

High automation

Production Rrocess

- Water Treatment System

- Bottle Blowing Machine

- Samit Bottle Water Filling Machine

- Drying Machine

- Labeling Machine

- Date Printer

- Packing Machine

Detailed Parameters

| Model | CGF8-8-4 | CGF14-12-5 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 | CGF60-60-20 |

| Capacity (500ML) | 3000BPH | 4000BPH | 8000BPH | 12000BPH | 15000BPH | 18000BPH | 24000BPH | 32000BPH |

| Floor Area | 300M² | 400M² | 600M² | 1000M² | 2000M² | 2500M² | 3200M² | 4000M² |

| Total Power | 100KVA | 100KVA | 200KVA | 300KVA | 450KVA | 500KVA | 650KVA | 800KVA |

| Operator Workers | 8 | 8 | 6 | 6 | 6 | 6 | 6 | 5 |

We specialize in designing and delivering customized 3–10L complete water filling line solutions, helping you achieve your production goals efficiently. Over the years, we have successfully reduced operating costs while maintaining long-term equipment durability and expanding design flexibility to meet diverse production needs.

Flexible for Multi-Bottle Production

Designed for flexible multi-bottle production, the 3–10L water filling line supports fast 15-minute bottle changeovers with PLC control, quick-change molds, and storage for up to 20 product settings—ideal for small and medium water plants.

Precision Filling with Green Efficiency

Made from food-grade 304/316L stainless steel, the system combines automatic CIP cleaning, ±0.5% high-precision volumetric filling, anti-drip nozzles saving up to 50,000 liters of water annually, and 30% lower energy consumption for hygienic, eco-friendly, and cost-efficient production.

Reliable Service & Smart Protection

Equipped with core components from trusted German and Japanese brands, the line features an intelligent early-warning system and is backed by SOKOS’s one-year warranty, 24/7 remote support, and on-site engineer service—ensuring stable, worry-free long-term operation.

Equipment Showcase

8 flushing heads, 8 filling heads and 4 capping heads, achieving a stable production capacity of 3,000-4,000 bottles/hour

8 flushing heads, 8 filling heads and 4 capping heads, achieving a stable production capacity of 3,000-4,000 bottles/hour

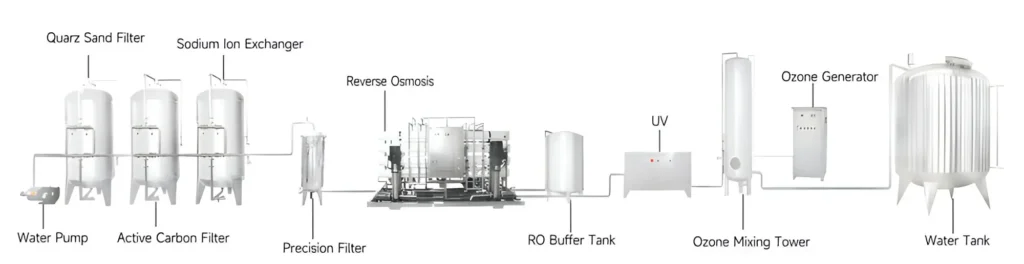

Water Treatment System FLOW DIAGRAM

Detailed Parameters

| Project Name: Automatic Rotary Type 10L Water filling line | ||||

| Project Name: Automatic Rotary Type 3-10L Big Bottle Filling Machine | ||||

| Bottle Material | Bottle Shape | Filling Volume | Cap Type | |

| PET / PE | Round | 3L-10L | Plastic Cap / Metal Cap | |

| Accuracy | Power Voltage | Control Voltage | Control | |

| ±0.5% | 380 V 50HZ 3phase+N+G | 24 V DC/AC | PLC + Touch Screen | |

| Packaging System | Palletizing System | |||

| Packing System | Min, Spec. | Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic | ||

| PE Film Carton Box | 1 | |||

| 2×3 | ||||

| 3×4 | ||||

| 4×6 | ||||

| 3×5 | ||||

| User Ambient Conditions | Temperature: 10~40℃ Humidity: No dew | |||

| User Electrical Supply Specification | Voltage: 380V±5% 3phase Frequency: 50HZ±1% | |||

We provide high efficiency and fully automatic 5-gallon/18.9L filling machine line for barreled water, bottled water and liquid packaging with large capacity. The system is an integration of washing, filling, capping, labeling and auxiliary drinking, and is suitable for application in drinking water plants, beverage producers and food processors.

The 5-gallon water filling line is designed with a modular structure and can be adapted to multiple container sizes (standard 5-gallon 18.9L bottle) and PC & PET barrels, empowering you to face various production challenges flexibly and reliably.

Core process flow

High-precision 5 gallon filling machine technology

We adopt an advanced gravity filling technology to ensure that the filling error of the 5 gallon filling machine (about 18.9 liters) of liquid per barrel is ≤±0.5%, avoid leakage or insufficient filling, and improve product consistency.

Multi-material compatibility

Adapt to PC barrels, PET barrels and other containers of various materials, support different barrel sizes (such as square/round barrels), can quickly change molds, and flexibly respond to diverse production needs.

Intelligent fault diagnosis system

Integrated PLC + touch screen control, real-time monitoring of production line status, automatic warning of abnormalities such as barrel blockage and leakage, reducing downtime, and improving maintenance efficiency by more than 30%.

Fully automated 5 gallon filling machine operation

We automate the machine process from empty barrel cleaning, disinfection, filling, capping to labeling, reduce manual intervention, and make the production efficiency reach 100-3000 barrels/hour (depending on the configuration), greatly reducing labor costs.

Food-grade hygiene standards

Key components are made of 316 stainless steel, comply with GMP, FDA or QS certification, and are equipped with a CIP online cleaning system to ensure that the filling process is pollution-free, suitable for drinking water, beverages and other food industries.

Energy-saving and environmentally friendly design

Equipped with a circulating water utilization device and a low-energy power system, water and electricity consumption are reduced by 15%-20% compared with traditional production lines, in line with the trend of green production.

Detailed Parameters

| Full Automatic Complete 60-1200BPH 3-5 gallon Barrel Filling Production Line | Mineral Water / Pure Water | |||

| Material | Shape | Filling Volume | Filling Type | Conveyor Mode |

| PC / PET | Round | 5 Gallon | Gravity filling Normal temperature | Conveyor belt |

| Adjustable Specifications of Bottle Type | Size of Barrel : ф276×490mm | |||

| Customers need to buy additional change-over parts for the different bottles. If using square bottles, then bottle separating system will be added. | ||||

| Container Label & Control Mode | Sticker Label / PVC shrink sleeve label | |||

| User Ambient Conditions | Temperature: 10~40℃ Humidity: No dew | |||

| User Electrical Supply Specification | Voltage: 380V±5% 3phase Frequency: 50HZ±1% | |||

Application Scenario

At MG Machinery, we deliver fully integrated, turnkey bottled water production lines engineered for efficiency, hygiene, and scalability. Our systems support PET, glass, and aluminum containers with capacities from 5,000 to 36,000 bottles per hour.

Cooperation Process: Confirm requirements → Design bottles and labels → Design overall production line solution→ Confirm solution →Arrange production →Shipment→Installation→training

Customer Cases

Product: Mineral water

Country: South Africa

Bottle size:500ml/1500ml

Capacity: 22000 bph

Product:5 gallon

Country:Saudi Arabia

Bottle size:20L

Capacity:1000 bph

Product:Glass bottle water

Country:Thailand

Bottle size:480ml

Capacity:18000 bph

we’re here to all your questions

hat is a 1L Water Filling Line and How Does It Work?

1L water filling machine is an automatic system that rinses, fills, and caps 1-liter bottles efficiently, ensuring hygiene, accuracy, and high production speed for bottled water plants.

What Is a 10L Water Filling Line and How Does It Work?

3-10L water filling machine is an automated system used to rinse, fill, and cap 10-liter bottles. It works through precise volume control and hygienic filling technology, ensuring fast, clean, and stable operation for pure or mineral water production.

What is the function of a 5 gallon water filling machine?

5 gallon water filling machine is designed to automatically wash, fill, and cap large water bottles, ensuring high hygiene, precision, and fast production for water plants.

How to maintain a 5 gallon filling machine properly?

Regularly clean pipes, replace worn parts, and check sealing systems to keep stable operation, extend lifespan, and ensure water purity and safety.

A Filling Solution That Doubles Efficiency

— Proven by 100+ Factories

Tell us your product, and we’ll match you with the most suitable filling solution.