Can Filling Machine

High-Speed Can Filling Machine | Beer & Beverage Can Filler Line

You are here: Home » Can filling machine

Swiss-Level Precision for Your Canning Line

Experience the best in packaging with MG Machine, a company you can count on. We are specialists in high-end can filling and seaming equipment, with the reliability of proven technology coupled with the sealing technology of Swiss Ferrum.

From craft breweries, new sparkling water brands or the expanding large-scale producers, MG Machine’s can seaming technology is focused on being easy to operate, highly efficient and durable – assisting in driving performance and lowering total cost of ownership.

Why Our Can Filler Stands Apart: The Ferrum Technology Edge

Our beverage can filling machine series is built around a core of superior engineering. We move beyond conventional designs to offer a solution that guarantees uptime and consistent quality.

Uncompromising Hygiene & Durability

The whole body of our can seamer is made of 304 stainless steel, with polished and brushed surface. This gives a clean and professional look and more important enables you to clean thoroughly and easily in your plant the highest food grade hygiene standard.

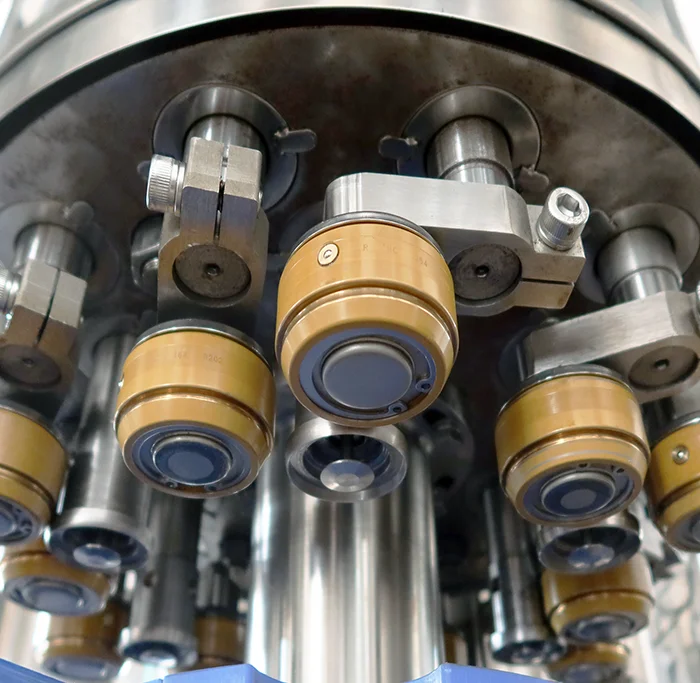

The Heart of Reliability: Swiss Ferrum Sealing Mechanism

This seamer incorporates the Swiss Ferrum technology that is licensed and recognized for its small-size and high precision. With tens of thousands in operation worldwide, it is proven to perform reliably even in the most challenging production environments.

Using a precision-machined alloy steel cam, instead of springs to regulate roller movement, this is not a spring based seamer. The solution: double-cam technology for smooth synchronization, reduced wear and the elimination of fatigue and breakage to the springs and associated blade downtime.

Premium Components for Longevity

The seaming rollers are made of high hardness 9Cr18MoV alloy steel and is heat treated and machined to precision. This allows for outstanding wear resistance running on a perfect seal for millions of strokes resulting in less maintenance cost.

User-Centric Adjustability

The machine includes a built-in height adjustment that is simple to use. With a reducer-based chain transmission the machine can be adapted by the operator to different can heights in a matter of seconds, reducing changeover time and increasing line flexibility.

Technical Specifications

Our range is designed to scale with your production goals, from mid-range to ultra-high-speed output.

| Model | GDF12-1 | GDF18-4 | GDF32-6 | GDF40-6 | GDF54-6 |

|---|---|---|---|---|---|

| Capacity (Cans/Hour) | 2,000 | 8,000 | 15,000 | 20,000 | 30,000 |

| Suitable Container | Aluminum Can / Tin Can / Plastic Can | ||||

| Can Diameter Range | Dia. 50mm – Dia. 99mm | ||||

| Can Height Range | 70mm – 175mm | ||||

| Filling Principle | Isobaric (Counter Pressure) / Normal Pressure | ||||

| Total Power | 2.4 kW | 4.4 kW | 6.2 kW | 7.2 kW | 16 kW |

| Dimensions (LxW) | 2.5 x 1.9 m | 2.8 x 1.9 m | 3.2 x 2.5 m | 3.8 x 2.8 m | 3.8 x 2.8 m |

| Height | 2.3 m | 2.5 m | 2.5 m | 2.5 m | 2.5 m |

| Weight | 2,500 kg | 3,200 kg | 4,500 kg | 6,500 kg | 10,000 kg |

Note: The can filling machine price varies based on model, configuration, and optional features. Contact us for a detailed quote tailored to your needs.

End-to-End Can Beverage Production Line Solutions

We are more than just beverage machine manufacturers; we are your partner in building a complete, efficient plant. Our expertise covers the entire journey—from concept and container design to process engineering and marketing support.

Upstream Processing

Water Treatment System, Beverage Mixing System

Can Handling

Depalletizer, Empty Can Washer

Core Process

Can Filling and Sealing Machine, Pasteurization/Sterilization Tunnel, Can Dryer

Downstream Packaging

Can Turner, Inkjet Printer, Labeling Machine, PE Film Shrink Wrapper or Case Packer.

Production Capacity

Configurable from 500 to over 18,000 BPH (based on 330ml cans).

Versatile Application Across Industries

Our can filling machines are engineered to handle a vast spectrum of liquid products, making them a versatile asset for multiple sectors:

Beer & Craft Breweries

Perfect for lagers, ales, and hard seltzers. The gentle filling preserves carbonation and flavor integrity.

Juices & Soft Drinks

From clear fruit juices and vitamin waters to pulpy nectars and carbonated sodas (CSD). (Ideal as a counter pressure can filler for carbonated drinks)

Ready-to-Drink (RTD) Beverages

Excellently suited for iced tea, coffee drinks (latte, mocha), plant-based milks (oat, almond), and energy drinks.

Wine & Cocktails

Growing segment for canned wines and pre-mixed cocktails. (Relevant to wine filling machine inquiries)

The Difference: Ferrum Cam Tech vs. Spring Systems

| Feature | MG Machine (Ferrum Cam Tech) | Conventional Seamers |

|---|---|---|

| Sealing Force Control | Precision alloy steel cam curve ensures consistent, repeatable motion. | Spring tension applies and controls seaming pressure. |

| Wear & Tear | Virtually no consumable parts in the seaming head. Mechanism is durable and long-lasting. | Springs are a high-wear component prone to fatigue, weakening, and breakage over time. |

| Maintenance & Downtime | Extremely low maintenance. No regular spring replacement needed. Maximizes uptime. | Requires regular inspection and replacement of springs. Unplanned downtime is common due to spring failure. |

| Seal Consistency | Cam-driven action provides a perfectly consistent, high-quality seam on every can. | Seal quality can degrade as springs weaken, leading to potential leaks or inconsistent seams. |

| Total Cost of Ownership | Higher initial investment, significantly lower lifetime cost due to reliability and minimal parts replacement. | Lower upfront cost, but higher ongoing maintenance and downtime costs. |

Client Testimonials & Industry Recognition

“Moving up to the MG Machine GDF32-6 line with the Ferrum seamer was a strategic move. Our down time on seamers has gone to almost nothing. The uniformity of seal quality has also really reduced the waste in our packaging.

This ain’t just a machine, it’s production insurance.” “Entering the canned wine category for the first time as a developing winery we were looking for a dependable partner. MG Machine not only offered a wine filling machine but also advice on can specifications and line configuration. Their support has been invaluable to our success at launching.” — Owner, Boutique Winery & Cidery

we’re here to all your questions

What makes your can seamer more reliable than others?

Our key advantage is licensed Swiss Ferrum cam technology. Unlike spring-based seamers that wear and fail over time, the cam-driven system has almost no consumable parts, delivering higher uptime and lower maintenance costs.

Can one machine handle both carbonated and still drinks?

Yes. Our fillers support both isobaric and normal pressure filling, making them suitable for CSD, beer, as well as still products like juice and wine.

What is the lead time for the GDF40-6?

Lead time typically ranges from 45 to 85 days after order confirmation, depending on configuration and production schedule.

Do you supply complete canning lines?

Yes. We offer turnkey solutions covering layout design, equipment supply, installation, commissioning, and operator training, from depalletizing to final packaging.

How can I get an accurate price?

Pricing depends on capacity, configuration, and optional features. Contact us with your beverage type, can size, and target output for a customized quotation.