Packaging system

Complete End-of-Line Packaging Systems for Beverage & Liquid Production

You are here: Home » Packaging system

High-Efficiency Automated Packaging Solutions

With a strong reputation for high quality end of line machinery, MG is able to offer full turnkey end of line solutions. Our solutions for bottle bundling, secondary packaging, and palletizing for shipment ensure maximum speed, stability and reliability.

MG develops packaging solutions for bottled water, carbonated drinks, juice, tea and functional beverages. Our automated packaging machines contribute towards reducing your production cost by ensuring product integrity, and line efficiency, making smart automation a critical investment in today’s competitively evolving production lines.

Packaging That Protects and Performs

Manual or inefficient end-of-line processes create severe bottlenecks. Proper automated packaging is not an expense; it’s a safeguard for your product and your profit margin.

The High Cost of Not Automating Your Packaging Line

| Aspect | With Automated Packaging System | Without / With Inadequate Packaging | The Risk & Consequence |

|---|---|---|---|

| Product Protection | Secure, uniform packs prevent tipping, scratching, and damage during handling and transit. | Loose, unstable bundles lead to frequent falls, breakages, and leaks. | High product loss/waste, customer returns, and damaged brand reputation. |

| Production Efficiency | Synchronized speed with upstream filling/capping lines (up to 36,000 BPH). No bottleneck. | Manual packing creates a severe bottleneck, limiting overall line output regardless of filler speed. | Underutilized capital investment in faster upstream machines. Lower overall plant productivity. |

| Labor & Cost | One operator can supervise multiple machines. Consistent, predictable output. | High labor intensity, fatigue-related inconsistencies, rising wage costs, and recruitment challenges. | Spiraling and unpredictable operational costs. Difficulty in scaling production. |

| Load Stability & Safety | Forms uniform, interlocked pallet loads stable enough for safe forklift transport and high stacking. | Irregular manual stacking leads to unstable pallets, risking catastrophic collapse in warehouse or truck. | Major safety hazard for workers, potential for massive product loss, and supply chain failures. |

| Presentation & Branding | Creates tight, professional-looking retail-ready packs (shrink film) or neat cartons. | Inconsistent, loose, or torn packaging appears unprofessional on store shelves. | Weakens brand perception and consumer trust, directly impacting sales. |

Core Packaging Machine Showcase: Engineered for Reliability

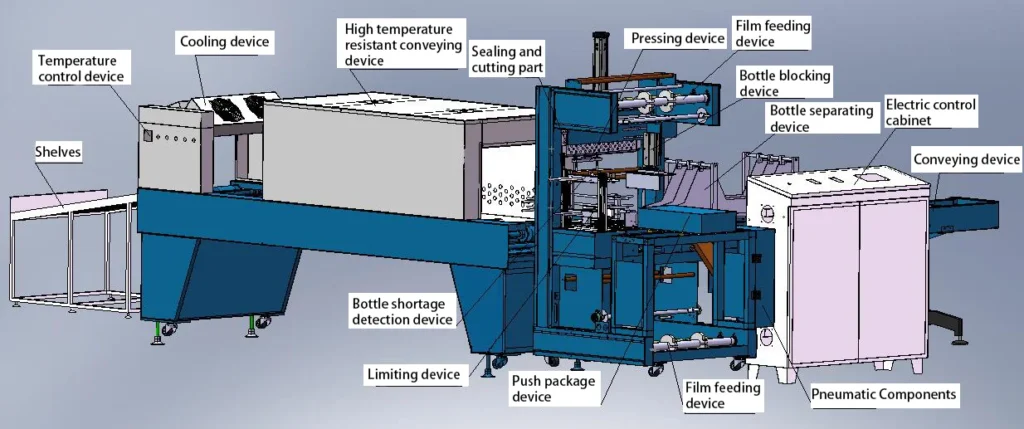

The automatic shrink film wrapping machine is suitable for small emerging brands as well as large scale production. So clean, retail-ready multi-packs are produced where speed, stability, and appearance are paramount – ideal for secondary packaging.

Bottles are grouped automatically, wrapped with a layer of ldpe film, then heat sealed and tightly shrunk in the heat tunnel to make safe, clear packs. The round, square and flat bottles can be processed with this machine, and it can be packed in 4×3, 6×1 and 3×2 common packing modes for use as tamper-evident or promotion-ready packaging.

Automatic Hot Melt Glue Carton Packing Machine

This automatic case packer packsh products in to stiff RSC boxes for good protection during shipping and transportation. Its sturdy construction guarantees consistent operation in high production environment.

The system erects cartons, folds bottles or cans into predetermined patterns, and seals the top and bottom carton flaps utilizing rapidly setting hot melt adhesive to form stiff, stackable cartons for best protection in handling and transport.

MG’s layout used the compact drop-type packing configuration without discounting the efficiency. With a premium Nordson hot melt system and more than 95% European electrical components like Schneider PLC and HMI, the machine brings you good consistency. It operates at 15–20 cases/min and consumes 8–10 kW.

Low-Level Mechanical Palletizer

This system represents the ultimate level in automation, as the pallets are formed directly from the conveyor, resulting in stable and uniform pallet loads. It simplifies the end-of-line processing while providing consistent pallet performance.

The palletizer takes shrink wrapped packs or cartons as input and stack them in predetermined patterns to create complete pallets for fork lift handling. It replaces heavy manual labor, enhancing safety while producing consistent, dependable results day and night.

MG’s side-infeed, low level design reduces the overall cost of ownership and saves valuable floor space. Powered by a Siemens PLC which has preset patterns and a touch-screen HMI, the machine is fully safeguarded. It’s capable of handling up to 10 layers per minute, standard pallet dimensions of 1100×1100 mm or 1200×1000 mm, and a pallet magazine that holds 8–10 blank pallets.

Application-Based Packaging Solutions

You Then What Is the Best Configuration for Your Packaging Needs? High-speed shrink wrapping is used for bottled water and CSD in 6-, 12- or 24-packs, and then automatically palletized for streamlined logistics. Juice and tea in glass or premium PET are best packed in cartons, which add strength and protection for the weightier vessels.

Functional and dairy drinks also use shrink wrapping with a half-tray for a combination of premium shelf look and enhanced bottom stability. High-speed wrap-around carton packing or shrink wrapping can be used for canned drinks, multi-product plants rely on versatile, modular lines capable of switching quickly between shrink and carton formats for speedy changeovers.

Technical Specifications Comparison

| Parameter | Shrink Film Wrapper | Hot Melt Carton Packer | Low-Level Palletizer |

|---|---|---|---|

| Primary Function | Create retail multi-packs | Pack into shipping cases | Stack cases/packs onto pallets |

| Typical Input | Loose bottles/cans | Loose bottles/cans | Shrink packs or sealed cartons |

| Typical Output | Film-wrapped bundle | Sealed RSC carton | Stable pallet load |

| Max Speed (Approx.) | 20+ packs/min | 20 cartons/min | 10 layers/min |

| Key Consumable | LDPE Shrink Film | Hot Melt Glue, Carton Blanks | Stretch Wrap (Post-Process) |

| Core Technology | Servo Film Feed, Heat Tunnel | Hot Melt Glue System, Cartesian Robot | Layer Forming, Push Plate |

| Control System | PLC + Servo Drives | Schneider PLC | Siemens PLC |

| Best For | Retail-ready packaging, promotions | Long-distance shipping, warehouse storage | Full line automation, labor saving |

Built for Integration, Reliability, and Long-Term Value

You MG is your reliable packaging machine maker which provides systems that are easily integrated with filling and labeling equipment manufacturers. We make project management easier and start up commitment more efficient and effective by giving you a single source of responsibility for line performance from day one.

Designed for maximum uptime, MG equipment is constructed from AIRTAC pneumatics, Siemens and Schneider controls, and heavy-duty machine frames to meet the demands of your 24/7 beverage production. Our designs are ready for the future featuring modular software and adaptable mechanical platforms for new products all supported directly by the manufacturer – from installation and commissioning to remote troubleshooting and real spare parts.

we’re here to all your questions

How do I choose between Hot Melt Glue and Self-Adhesive labeling?

It depends on label type and speed. Hot Melt (OPP roll labels) is best for very high-speed, cost-effective labeling of round bottles. Self-adhesive machines suit medium speeds, variable bottle shapes, and fast changeovers, common in cosmetics and pharmaceuticals.

What’s the difference between semi-automatic and full-automatic sleeve labelers?

Semi-automatic machines (up to about 9,000 BPH) require manual sleeve placement. Full-automatic systems apply and shrink sleeves automatically and are ideal for integrated lines above 10,000 BPH.

Can MG machines handle frequent label or bottle changes?

Yes. MG self-adhesive and sleeve labelers support quick changeovers using adjustable parts and PLC recipes, allowing switches in minutes.

Do you supply standalone machines or full line integration?

Both. MG can provide a single labeling machine or fully integrate the labeling section with conveyors, unscramblers, and inspection systems.

How is after-sales support and spare parts handled?

MG offers lifetime technical support, a 2-year parts warranty, full installation and training, and fast global spare parts delivery.