Palletizer & depalletizer

Automated Palletizing & Depalletizing Systems: Maximize Line Efficiency & Minimize Labor

You are here: Home » Palletizer & depalletizer

High-Speed Palletizing & Depalletizing Automation

MG offers state-of-the-art layer palletizers and depalletizers that make your handling of materials a very easy and automation-friendly task. Our products are perfectly adapted to interface with the upstream and downstream production process to obtain a smooth and consistent product flow with minimum interruption.

You can increase your productivity and reduce workplace injuries and labor costs with our systems – from unloading as many as 48,000 bottles per hour to building stable, warehouse-ready pallets. Precision, speed and reliability combined enable MG to deliver a stable and efficient production line to meet the demand in today’s manufacturing.

From Manual Handling to Robotic Precision

Manual pallet handling is one of the most labor-intensive, inefficient, and injury-prone points in any production facility. Automating this process is a direct investment in operational excellence.

Manual Process vs. Automated System: A Critical Comparison

| Aspect | With Automated Palletizer/Depalletizer | With Manual Handling | Impact on Your Bottom Line |

|---|---|---|---|

| Speed & Throughput | Consistent, high-speed operation (e.g., 0-48,000 BPH). Uninterrupted flow matching line speed. | Slow, variable, and creates a severe bottleneck. Pace declines due to fatigue. | Limits overall plant capacity. You cannot run your filler or packer at full speed. |

| Labor & Operational Cost | 1-2 operators can supervise multiple lines. Eliminates 3-5+ full-time manual handlers per shift. | Requires multiple workers per shift for repetitive, heavy lifting. High ongoing wage and insurance costs. | Significant, recurring labor savings. Rapid ROI (often <2 years). Mitigates rising wage and recruitment challenges. |

| Load Quality & Safety | Builds perfectly uniform, interlocked pallets every time. Ensures stable, safe loads for transport and high stacking. | Inconsistent patterns lead to unstable, leaning pallets. Major risk of collapse, causing product loss and serious workplace injuries. | Eliminates product damage in transit and warehouse. Drastically reduces workplace accident liability and insurance claims. |

| Product Integrity | Gentle, layer-based handling (gripper or sweep) minimizes contact and risk of damage to bottles, cans, or packs. | Frequent drops, impacts, and rough handling cause scratches, dents, and leaks. | Reduces product waste and customer returns. Protects brand reputation for quality. |

| Flexibility & Changeover | Press one button to change the type of stacking. Software-programmable patterns for different products or pack types. | Manual retraining and physical reconfiguration required for each new product. Slow, error-prone. | Enables agile, low-cost production of SKUs. Faster response to market demands. |

Core Products — Built to Work Together

Our systems are designed to work in harmony—depalletizers feed your line, and palletizers close it—creating a continuous, automated loop.

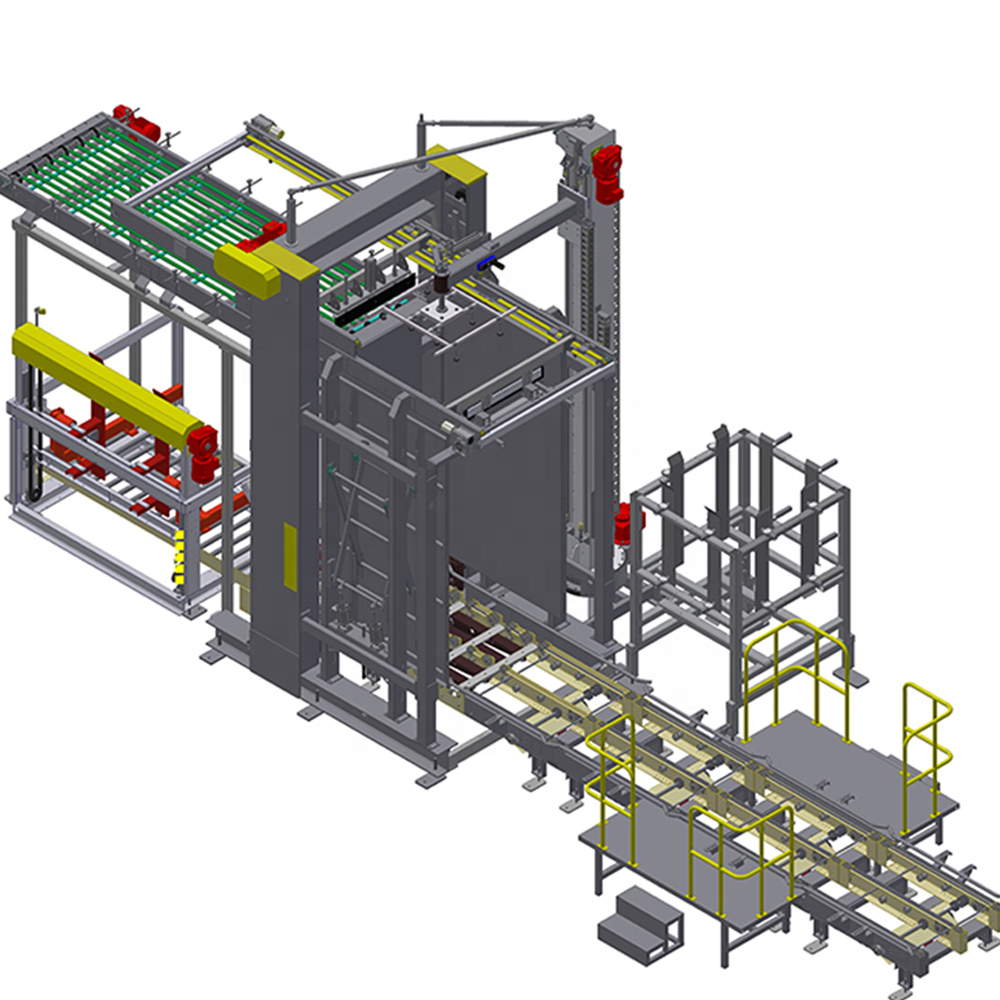

High-Capacity Automatic Depalletizer – Efficient Line Starter

MG’s automatic depalletizer is designed to gently depallet full layers of empty PET bottles, glass bottles, aluminum cans or HDPE containers from incoming pallets, and place them single file onto the conveyor transferring to your rinser or filler. This provides a steady, non-stop flow of containers to the high-speed production line.

Complete-Layer Clamping is one of the key features for efficiency. BXDJ model, layer-by-layer whole layer lifting, speed up to 48,000bph, to keep your high speed filler always full avoid any stop or bottle neck.

MG offers two design options to suit your plant layout: Low-Level, where the pallet stays on the floor and the gripper moves down, or High-Level, where the pallet is raised and the gripper is stationary. Quick Specs for the BXDJ-600: max speed 48,000 BPH, intelligent HMI control with real time status and alarms, whole-layer gripper handling, approximately 4.0 KW power consumption.

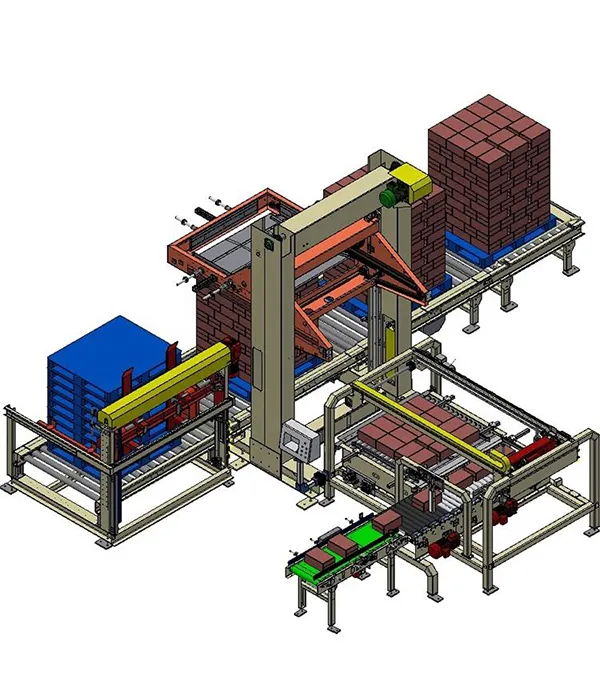

Flexible Automatic Palletizer – Efficient Line Finisher

MG’s fully automatic palletizer easily takes finished goods—be they shrink packs, cartons, or bottles—off the packaging machines and stacks them in accurate, stable layers on pallets for delivery to the warehouse or for shipping. This results in orderly processing with smooth logistics on the downstream side.

Dual-Mode Flexibility is a true efficiency enhancer. MG provides Mechanical Gantry-style palletizers for uniform/single pack offering high speeds per hour and Robotic Palletizing Cells for full/partial mixed-SKU or multi-pack palletizing solutions offering the highest level of flexibility due to multi pack configurations.

Our low-level, side-infeed layout reduces the footprint, with pattern changes made instantaneously through the PLC touchscreen with no mechanical modifications necessary. Gantry Type Quick Specs: Speed >10 layers/min, various software-selectable and patterns, Siemens PLC with premium components (SEW drives, Lenze Servo), Multiple line integration capability.

Application-Based Solutions: From Beverage to Home Care

Beverage Production (Water, CSD, Beer): Fast empty glass/PET bottle depalletizer → Filling Line → High-speed palletizer for finished cases or shrinkwrapped packs.

Food & Edible Oil: Gentle depalletizing of glass jars → Filling/ Capping → Palletizing of closed cartons.

Cosmetics & HPC (Home & Personal Care): Robotic palletizer line capable of processing multiple carton sizes and mixed loads for distribution.

Canning Lines: High-speed can depalletizer → Filling/seaming → Palletizer for trayed or shrink-wrapped can packs.

Technical Specifications at a Glance

| Parameter | BXDJ Series Automatic Depalletizer | Sunswell Gantry Palletizer |

|---|---|---|

| Primary Function | Unload empty containers onto line | Stack finished packs/cartons onto pallets |

| Typical Material | Empty PET/Glass Bottles, Aluminum Cans | Shrink Packs, RSC Cartons, Boxes |

| Handling Method | Whole-Layer Gripper Head | Layer Forming & Sweep/Push Plate |

| Max Speed (Approx.) | 48,000 Bottles/Hour | 10+ Layers/Minute |

| Key Efficiency Tech | Multi-buffer design for smooth flow | Instant pattern change via PLC software |

| Control System | Intelligent HMI, PLC, Frequency Inverter | Siemens PLC, SEW Gear Motors, Lenze Servos |

| Footprint & Layout | Low-Level or High-Level options | Compact, low-level side infeed |

| Ideal For | High-speed feeding of fillers | End-of-line automation, labor replacement |

The MG Engineering Advantage – Reliability in Every Component

MG systems are designed to be dependable around the clock and are built with long-term stability and maximum uptime in mind for high load production.

In order to achieve precision motion, safety and durability, we incorporate proven, quality components including SEW gear motors, Lenze servo motors, Schmersal slewing bearings, INA/FAG bearings and Walker precision air filtration.

For a stable system and user friendliness, MG combines Lanny proportional valves and Eugen Seitz high-pressure valves with a user friendly HMI featuring real time monitoring, alarms and safety interlocks for safe and efficient operation.

we’re here to all your questions

What is the main difference between a low-level and high-level depalletizer?

Low-level systems keep pallets on the floor and pick layers downward; high-level systems lift the pallet to a fixed working height. Selection depends on space and maintenance preferences.

Can your palletizer handle different package types on the same line?

Yes. Multiple pack “recipes” are stored in the PLC and can be changed instantly via the touchscreen—no mechanical adjustments required.

How do you protect bottles during high-speed depalletizing?

Smooth conveyor buffering and precise gripper motion control minimize impact, tipping, and product damage.

How compact are these systems?

The low-level, side-infeed design offers a small footprint, ideal for space-limited facilities.

What about maintenance and spare parts?

Premium global components ensure reliability, easy spare part availability, and simple routine maintenance.