R&D Center

You are here: Home » R&D Center

R&D Design Team

Professional design

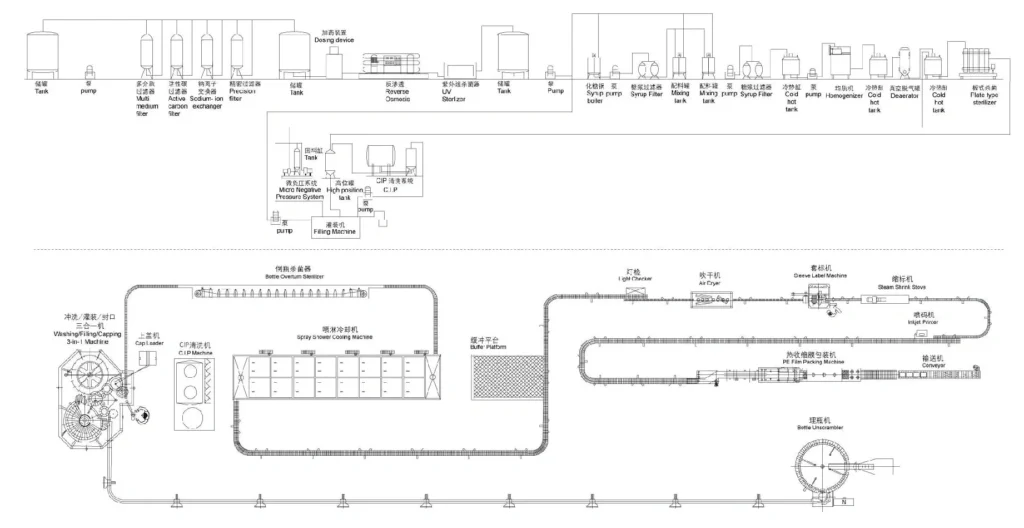

Our skilled engineers customize high speed filling machines to your production requirements. With the aid of leading edge software solutions like SolidWorks, AutoCAD, Siemens TIA Portal, ANSYS and EPLAN, we bring dependable products to the market for both liquid and viscous solutions.

From linear fillers to fully automated intelligent systems, every model complies with rigorous hygiene standards. Whether it’s a modular upgrade or a complete turnkey line solution, our team is dedicated to lean, accuracy and continuous innovation.

Manufacturing Team

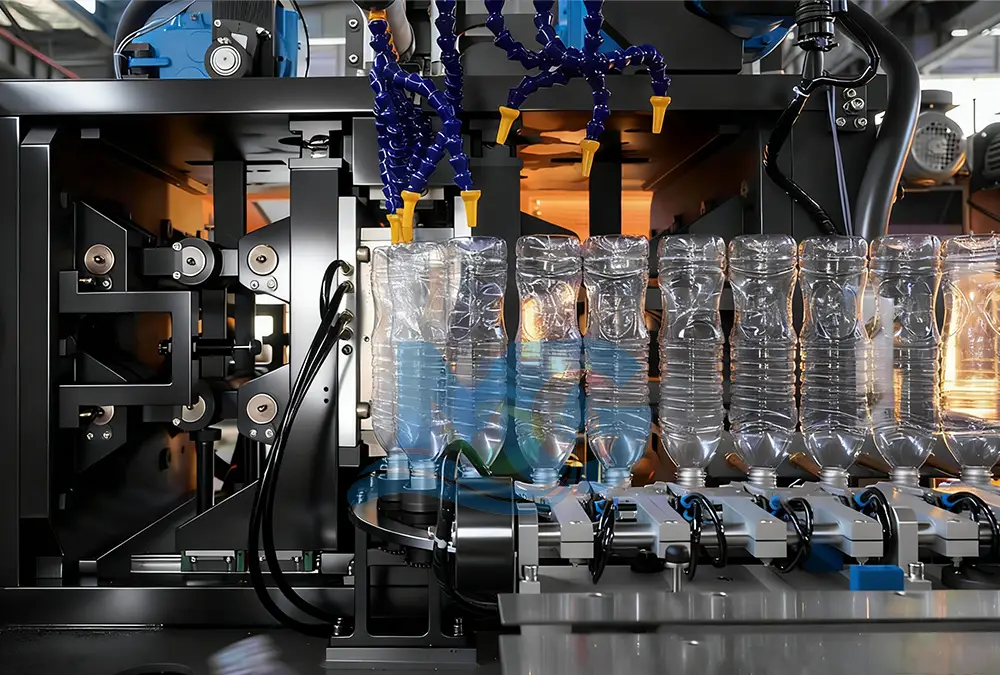

With ISO-certified MG production, we can design filling machines that offer high performance, accuracy and long service life. Utilizing advanced machinery including CNC machining, laser cutting and robotic welding, our talented technicians are able to produce components with tight tolerances.

The assembly lines of MG are equipped with unified working procedures and well incorporated with servo motor and the use of sanitary stainless steel construction, best for water, oil, drinks and daily cleaning agent. Each machine is tested vigorously in house prior to shipment to guarantee perfect operation.

Quality Inspection Department

In our state-of-the-object testing, we perform leak test, filling accuracy, vibration, and material safety test on each machine to let our product reached international standard. Each filler is run for a 72 hour continuous operation test in a simulated production environment, and a full inspection documentation and performance report is provided for full disclosure.

MG follows the rigors of the ISO 9001 quality management system and is customer-centric in its approach to fulfilling requirements related to the FDA, CE, and GMP certifications.

After-Sales Team

With professional beverage machinery manufacturer capabilities, Sokos can provide dependable quality product as well as professional after-sales service. Our skilled Technical Team is at your service 24 / 7 online support with remote diagnostics, video instructions and even sending on site engineer support for a stable operation of your machines.

MG can also provide operators training, assistance for maintenance and trouble-shooting solutions to enable clients to start quickly and reduce down time. We design and supply original spare parts and with fast worldwide delivery, assuring you of our prompt support. For major projects,top level engineers can be sent ter piece to help you manage production line and a real turnkey service is provided.

A Filling Solution That Doubles Efficiency

— Proven by 100+ Factories

Tell us your product, and we’ll match you with the most suitable filling solution.