Water Filling Machine

Premium Bottled Water Filling Machine

You are here: Home » Water filling machine

MG: Making bottled water production easy

Aseptic processing/filling is a sophisticated process by which commercially sterile products are filled into pre-sterilized containers and sealed under sterile conditions.

Its fundamental basis is that the product, packaging material, filling environment and equipment are brought to the state of commercial sterility at the same time and are maintained in that state A This allows maximum shelf-life for the product to be stored at ambient temperature without preservatives.

3-in-1 Bottle Water Filling Machine

Unmatched Hygiene & Durability with 304 Stainless Steel

Made of 304 stainless steel, which is food grade, our water bottle filler is highly resistant to corrosion, easy to clean and very durable. This high grade material makes all components that touch your product safe, clean and reliable.

This heavy duty bottling line kit up is for constant operation, and the equipment life is much longer. You don’t have to worry about rust, contamination and product quality with our machine.

Engineered for Maximum Output & Precision

MG Automatic Bottle Filler Machine – The MG series is a fully automatic, high-performance liquid filler suitable for thin liquids at 2,500–32,000 bph. Designed for various bottle specifications, it efficiently meets different production needs while ensuring consistent quality.

Equipped with precise filling valves and a smart control system, the machine minimizes spillage and overfilling. It provides a reliable, cost-effective solution for high-volume bottling, helping factories achieve world-class production standards with ease.

Smart Operation & Reduced Downtime

With the advanced PLC control system, our bottling machine makes operation simple, monitoring in real time and adjustment quickly. Operators can easily control the entire process for efficient production with minimal interruptions.

With the fault detection automation system and energy saving modules integrated, the machine is smoothly running while minimizing cost of operation. This smart design makes your water bottling plant management simple and more effective.

Water Bottling Production Line

Technical Specifications & Model Comparison

Technical Specifications & Model Comparison

Find the perfect water bottling machine for sale from our range. Below are key parameters for our CGF Series bottle filling machines:

| Model | Capacity (500ml Bottle) | Main Motor Power | Dimensions (LWH) | Weight | Suitable Bottle Shape |

|---|---|---|---|---|---|

| CGF8-8-4 | 1,000 – 2,000 BPH | 2.2 Kw | 1.8×1.6×2.1 m | 2200 kg | PET Circular/Square |

| CGF14-12-5 | 3,000 – 5,000 BPH | 2.5 Kw | 2.3×1.7×2.4 m | 2500 kg | PET Circular/Square |

| CGF18-18-6 | 6,000 – 8,000 BPH | 3.0 Kw | 2.7×2.1×2.5 m | 3500 kg | PET Circular/Square |

| CGF24-24-8 | 10,000 – 12,000 BPH | 3.0 Kw | 3.1×2.3×2.5 m | 4000 kg | PET Circular/Square |

| CGF32-32-10 | 15,000 – 18,000 BPH | 3.0 Kw | 3.7×2.6×2.5 m | 5000 kg | PET Circular/Square |

| CGF40-40-12 | 18,000 – 20,000 BPH | 4.0 Kw | 5.0×4.0x2.5 m | 5500 kg | PET Circular/Square |

| CGF50-50-15 | 22,000 – 24,000 BPH | 7.5 Kw | 5.5×4.5×2.5 m | 6000 kg | PET Circular/Square |

| CGF60-60-20 | 26,000 – 32,000 BPH | 7.5 Kw | 6.0×6.0x2.5 m | 7000 kg | PET Circular/Square |

Key Product Knowledge Points:

Material: All product-contact parts are 304 Stainless Steel (316 optional).

Capacity & Customization: Handles 300ml-1000ml bottles; customizable for diameter (50-115mm) and height (160-320mm).

Operation: Fully automatic, with intelligent touchscreen control.

Lifespan: Designed for 10+ years of service with proper maintenance.

Connection: Standard industrial interfaces for easy integration into your water bottling system

Complete Water Bottling Equipment & Production Line

A full bottled water production line involves more than just a filler. We provide integrated, turnkey systems.

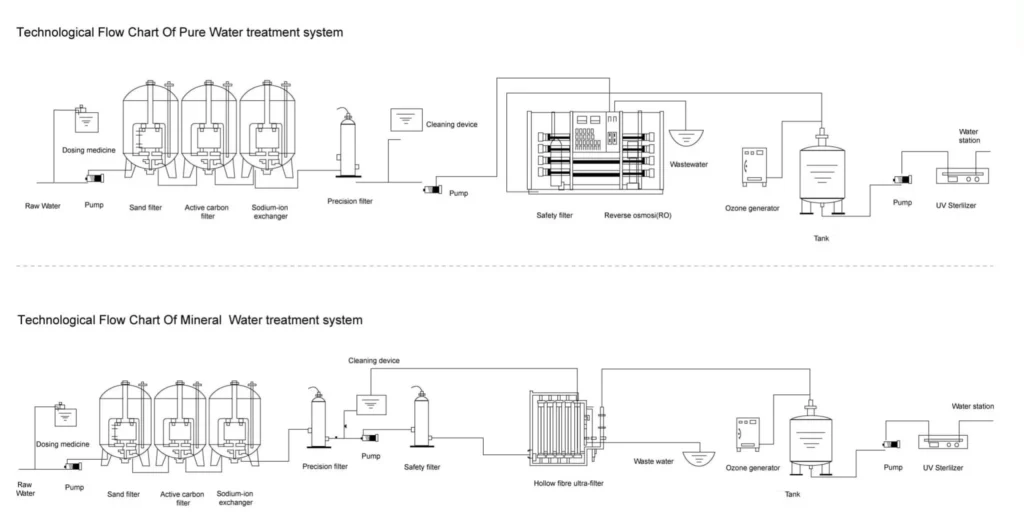

Water Treatment System

1.High Water Purity – Effectively removes impurities, bacteria, and harmful substances to ensure safe and clean drinking water. 2. Advanced Filtration Technology – Uses multi-stage filtration and treatment processes for stable and reliable water quality. 3. Energy-Saving Design – Optimized system reduces energy consumption and lowers operating costs. 4. Durable & Low Maintenance – Built with high-quality materials for long service life and minimal maintenance needs. 5. Flexible Application – Suitable for various industries including beverage, food, and bottled water production.

Product Description

Our water treatment equipment is engineered to provide safe, pure, and high-quality water for beverage, bottled water, and liquid food production lines. It combines advanced purification technology with durable design, ensuring reliable performance and compliance with international hygiene standards.

Working Principle

The system uses a multi-stage purification process to treat raw water:

Pre-Filtration – Removes large particles, sediments, and suspended solids to protect downstream equipment.

Activated Carbon Filtration – Adsorbs chlorine, organic compounds, odors, and harmful chemicals, improving taste and safety.

Reverse Osmosis (RO) – Forces water through a semi-permeable membrane to remove dissolved salts, heavy metals, bacteria, and viruses.

UV Sterilization / Ozone Treatment – Kills remaining bacteria and microorganisms to ensure microbiological safety.

Post-Polishing Filter (optional) – Provides final filtration to guarantee pure, crystal-clear water ready for bottling.

Advantages

High Water Quality: Ensures safe and stable water output that meets international beverage and food standards.

Energy-Efficient Design: Optimized components reduce energy and water consumption, lowering operating costs.

Durable & Low Maintenance: Built with high-quality materials, ensuring long service life and minimal maintenance.

Flexible Applications: Customizable for bottled water, juice, dairy, or other liquid production lines.

Intelligent Control: Automated monitoring and control systems allow easy operation and real-time fault detection.

Applications

This equipment is ideal for modern bottled water plants, beverage factories, dairy production, and any liquid food industry requiring high-purity water. Its modular design allows easy expansion and adaptation to various production capacities.

Bottle Blowing Machine

Our fully automatic bottle blowing machine delivers high-speed production with precise and consistent bottle quality. Its energy-efficient design reduces operational costs, while flexible mold options allow quick changes for different bottle shapes and sizes. Built with durable materials and advanced components, it ensures long service life, minimal maintenance, and reliable performance for modern beverage and packaging production lines.

Product Description

Our fully automatic bottle blowing machine is designed for high-speed, precise, and efficient production of plastic bottles for beverages, water, and other liquid packaging. Combining advanced automation technology with durable construction, it ensures consistent bottle quality and stable operation for modern production lines.

Working Principle

The machine operates through a fully automated stretch-blow molding process:

Preform Feeding – Preforms are automatically loaded onto the conveyor and carried to the heating section.

Preform Heating – Infrared heaters evenly heat the preforms to the optimal temperature for stretching and blowing.

Stretching & Blowing – Heated preforms are mechanically stretched and then blown into molds using high-pressure air, forming bottles with precise dimensions and uniform wall thickness.

Cooling & Ejection – Blown bottles are cooled within the mold to maintain shape, then automatically ejected for collection or further processing.

Advantages

High Efficiency & Consistency: Produces bottles rapidly with uniform size, shape, and quality.

Energy Saving: Optimized heating and pneumatic systems reduce power consumption and operational costs.

Flexible Production: Supports various bottle sizes and shapes with quick mold changes.

Durable & Low Maintenance: Constructed with high-quality materials for long service life and minimal downtime.

Intelligent Control: Automated monitoring and adjustments allow easy operation and stable performance.

Applications

Ideal for producing water, juice, carbonated drinks, dairy bottles, and other liquid packaging bottles. Its flexible design allows adaptation to small, medium, and large-scale production lines.

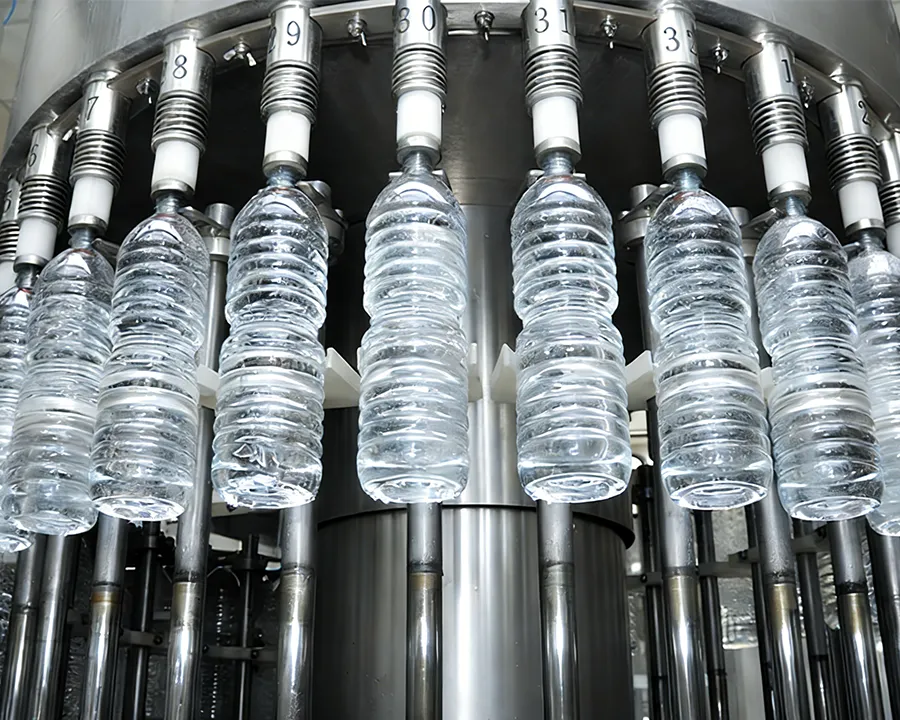

Water Filling Machine

Our water filling machine is made of high-quality 304 stainless steel, ensuring durability, corrosion resistance, and hygiene for safe water production. Designed for high efficiency, it delivers fast and precise filling to maximize output while minimizing downtime. The energy-saving design reduces power and water consumption, lowering operational costs. Equipped with an intelligent control system, it allows easy operation, real-time monitoring, and automated adjustments. Flexible and reliable, the machine adapts to various bottle types and production lines, providing stable performance for continuous operation.

Product Description

Our water filling machine is designed for efficient, precise, and hygienic bottling of water for various industries, including bottled water, beverages, and liquid food production. Constructed with high-quality 304 stainless steel, it ensures durability, corrosion resistance, and safe contact with water.

Working Principle

The machine operates through an automated rinsing, filling, and capping process:

Bottle Rinsing – Empty bottles are first cleaned with purified water to remove dust and contaminants.

Water Filling – Cleaned bottles are accurately filled to the required volume using gravity or vacuum filling technology, ensuring minimal spillage and high precision.

Capping/Sealing – Filled bottles are automatically capped or sealed, providing a tight, leak-proof finish.

Control & Monitoring – The intelligent control system manages all stages, allowing real-time monitoring, automatic adjustments, and fault detection to ensure stable and reliable operation.

Advantages

High Efficiency: Fast and precise filling to maximize production output.

Energy Saving: Optimized design reduces power and water consumption.

Hygienic & Durable: 304 stainless steel construction ensures safe contact with water and long service life.

Intelligent Operation: Automated control simplifies operation and maintenance.

Flexible Applications: Suitable for different bottle types and production capacities.

Applications

Ideal for bottled water plants, beverage factories, juice production, and other liquid food industries.

Labeling Machine

Our hot melt glue labeling machine delivers fast, precise, and reliable labeling for a wide range of bottles and containers. Equipped with advanced hot melt adhesive technology, it ensures strong, durable labels that adhere securely without damaging the packaging. The machine is designed for high efficiency, reducing downtime and increasing production output, while its intelligent control system allows easy operation, real-time monitoring, and automated adjustments. Durable construction and flexible compatibility with different bottle shapes and sizes make it an ideal solution for modern beverage, food, and liquid product lines.

Product Description

Our hot melt glue labeling machine is designed for fast, precise, and reliable labeling of bottles and containers in beverage, food, and liquid product industries.

Working Principle

- Bottle Feeding – Containers are automatically conveyed to the labeling station in a stable and consistent manner.

- Glue Application – The machine heats and melts adhesive, then applies a controlled amount to the label or container surface.

- Label Placement – Labels are accurately positioned and pressed onto the bottle or container, forming a secure bond.

- Pressing & Finishing – Rollers or brushes ensure smooth application and adhesion, removing air bubbles and wrinkles.

- Control & Monitoring – The intelligent system monitors speed, label position, and adhesive flow, allowing automatic adjustments for consistent performance.

Advantages

High Precision & Efficiency: Fast labeling with accurate alignment and minimal waste.

Strong & Durable Adhesion: Hot melt adhesive provides reliable bonding that resists peeling.

Energy Saving & Cost Efficient: Optimized heating and control systems reduce power consumption.

Intelligent Operation: Automated controls simplify operation and reduce manual intervention.

Flexible Application: Suitable for various bottle shapes, sizes, and materials.

Applications

Ideal for beverage, bottled water, juice, dairy, and other liquid product lines.

Packing Machine

Our bottle water shrink wrapping machine provides fast, efficient, and reliable packaging for bottled water. Using advanced heat shrink technology, it tightly wraps multiple bottles in film, ensuring stability and protection during storage and transport. Designed for high-speed production, it increases output while minimizing downtime. The machine’s intelligent control system allows easy operation, precise temperature and speed adjustments, and consistent wrapping quality. Durable construction and flexible compatibility with different bottle sizes make it an ideal solution for modern bottled water production lines.

Product Description

Our bottle water shrink wrapping machine is designed for efficient, reliable, and high-speed packaging of bottled water.

Working Principle

Bottle Feeding: Bottles are automatically aligned and conveyed to the wrapping station in stable rows.

Film Application: Heat-sensitive shrink film is fed around the bottles, covering them completely.

Sealing: The machine seals the film edges to ensure the bottles are securely wrapped.

Heat Shrinking: Heated shrink tunnels or chambers shrink the film tightly around the bottles, forming a neat, uniform package.

Control & Monitoring: Intelligent control systems regulate conveyor speed, temperature, and film tension, ensuring consistent wrapping quality and minimal waste.

Advantages

High Efficiency: Fast and reliable packaging to maximize production output.

Stable & Protective Packaging: Shrink film tightly secures bottles for storage and transport.

Energy Efficient: Optimized heating system reduces power consumption.

Intelligent Operation: Automated controls allow easy operation, monitoring, and adjustments.

Flexible & Durable: Compatible with different bottle sizes and configurations, built with high-quality materials for long-term use.

Applications

Ideal for bottled water production lines, beverage factories, and other liquid product industries.

Our hot melt glue labeling machine is designed for fast, precise, and reliable labeling of bottles and containers in beverage, food, and liquid product industries.

Key Applications & Industries

Our commercial bottle fillers are flexible and can be used for a wide range of commercial and industrial purposes: Bottled Water Plants: Manufacture aqua mineral and purified drinking aqua.

Beverage Companies: For still or sparkling water production. Food & Dairy: Processing delicate liquid foods. Startups & SMEs: Our small water filling machine price makes for an easy entry.

Volume production: High-speed bottling lines for the commercial bottling line equipment needs.

What makes MG different from other factories?

Premium Components & Reliable Performance

We source the components for our high quality transmissions as well as the precision actuators from reputable vendors, utilizing similar hardware as leading industry manufacturers such as Krones and Mitsubishi. Each component is subjected to rigorous performance testing and quality tracking, making sure that our bottle filling machinery complies to the industrial-strength continuous running criteria, which in return minimizes unexpected downtime.

Direct Factory Pricing & Stable Lead Time

As a professional water filling machine supplier&manufacturer, we could provide you best price of water bottle filling machine with no middleman cost. We exercise rigid control over the supply chain to ensure consistent and reliable delivery schedules, to alleviate concerns over fluctuating lead times.

Comprehensive Customization & Engineering Support

Looking for a particular configuration of bottling filling machine? Our engineering team deliver customised solutions. We tailor the line design and the bottle packaging machines to reduce your shipping and logistics costs, and can also provide modular designs to facilitate transport.

Strong After-Sales & Global Service Network

We tackle the issue of challenging after-sales service with an all-around support service from professional installation and commissioning instructions to operation and maintenance training, spare parts that are available and supported by a global logistics network, to remote online support and on-site service visits as an option.

we’re here to all your questions

What is the price range for a complete water bottle filling machine?

The water filling machine price varies greatly depending on automation level, speed, and configuration. A small water filling machine price for a basic 3-in-1 unit starts around $8000, while a full high-speed automatic water bottling line can be $58000+. Contact us with your capacity requirements for a precise quote.

Can your machine handle different bottle shapes and sizes?

Yes. Our PET bottle filling machines are highly customizable. The bottle filling machinery can be adjusted to handle circular, square, or custom-shaped PET bottles within a specified diameter and height range.

What about the water quality and treatment?

We are experts in water bottling equipment. We can provide the complete water treatment system (RO/UV/Ozone) needed to produce purified or mineral water that meets international safety standards.

How do you ensure the machine's durability and pressure resistance?

Our machines are built with thick, high-grade 304 stainless steel frames and pipelines, designed for industrial pressure (0.3-0.7 Mpa air supply). Key components are sourced for high-intensity operation, ensuring long-term pressure resistance and preventing leaks.

What is your after-sales service policy?

We offer a standard 12-month warranty. Our service includes free remote guidance, online spare parts catalog, and training manuals. We have service agents in multiple regions to provide timely support, ensuring you are never alone after purchase.